|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

to come in contact with skin, to

(6) Inspect the engine air-cooling system for

prevent burns. Use rubber gloves

bent or missing air shrouds.

when filling battery.

(7) After servicing as prescribed below, crank

the engine several times to make sure engine and

(4) Cold weather servicing.

Lubricate

magneto are free.

equipment in accordance with lubrication order (fig. 3-

1). Add sufficient anti-freeze to lower the freezing point

(8) Inspect publications for completeness.

of the radiator coolant to a safe margin below the

Inspect toolbox for damage and loose mounting.

anticipated temperature of the surrounding air, as shown

(9) Inspect fire extinguisher. Be sure it is

in table 2-1.

fully charged and in operating condition (para 2-20).

Note

(10) Inspect muffler for holes, corrosion, loose

Fasten a tag near the radiator filler

mounting.

cap indicating the type antifreeze.

2-4. Installation of Separately Packed Components

b. Servicing the Equipment.

a. Fill batteries with electrolyte as directed in

(1) Lubrication. Refer to LO 5-4320243-12

for lubrication of engine. Lubricate pump assembly in

accordance with Lubrication order (fig. 3-1).

(2) Preventive maintenance. Perform the

daily preventive maintenance services (para 3-6).

(3) Battery. Fill the battery with electrolyte to

2-5. Setting-Up Instructions

3/8 inch above the plates. The specific gravity, checked

a. Outdoor Installation. Where conditions permit,

with hydrometer, must read 1.280 or higher at a

avoid a muddy, sandy or dusty site. If unit must be

temperature of 80 F. Refer to TM 9-6140-200-15 for

installed on soft ground, arrange a foundation of

further information on service and care of batteries.

planking, logs or concrete.

b. Indoor Installation. Make sure the floor will

Warning

support a total weight of 10,000 pounds. Provide at

Take precautions against spilling

least four feet of space on all sides

electrolyte on clothing, or allowing

it

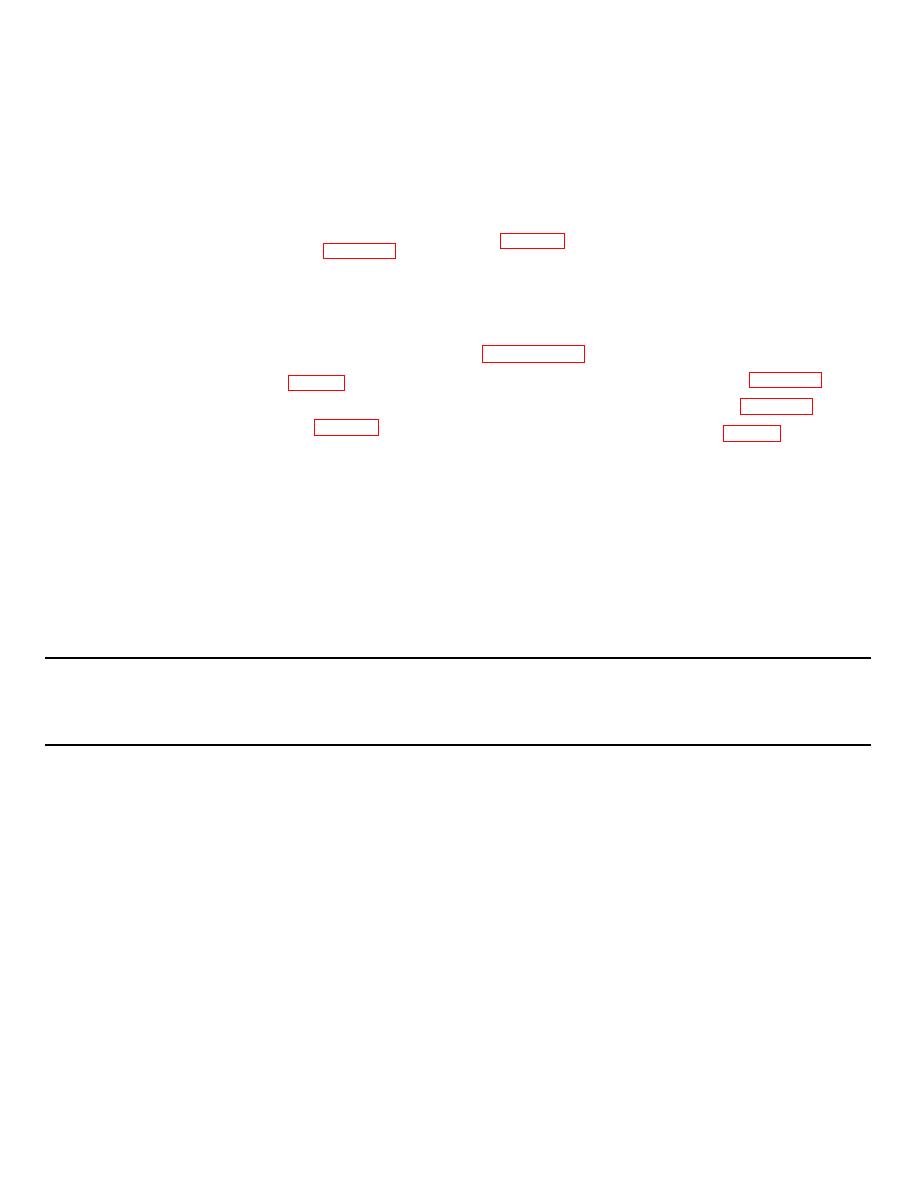

Table 2-1. Freezing Points, Composition, and Specific Gravities of Military

Antifreeze Materials

Lowest

Pints of

expected

inhibited

Ethylene glycol

ambient

glycol per

Compound, Antifreeze

coolant solution

2

temp.

gal. of

Artic

specific gravity

1

3

F

coolant

at 68F.

+20

112

Issued full strength and ready mixed for 0 to

1.022

+10

2

65F temperatures for both initial instal-

1.036

0

2a

lation and replenishment of losses

1.047

-10

3 1/4

1.055

-20

3 1/2

1.062

-30

4

1.067

-40

4 1/4

1.073

-50

Arctic Anti-

DO NOT DILUTE WITH WATER OR ANY

-60

freeze

OTHER SUBSTANCE

-75

preferred

1

Maximum protection is obtained at 60 percent by volume (4.8 pints of ethylene glycol per gallon of solution).

2

Military Specifications MIL-C-11755 Arctic type, nonvolatile antifreeze compound is intended for use in the

cooling system of liquid cooled internal combustion engines. It is used for protection against freezing primarily in Arctic

regions where the ambient temperature remains for extended periods close to -40 or drops below, as to low as -90 .

F

F

3

Use an accurate hydrometer. To test hydrometer, use 1 part ethylene kIycol antifreeze to 2 parts seater. This

should produce a hydrometer reading of 0F.

2-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |