|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

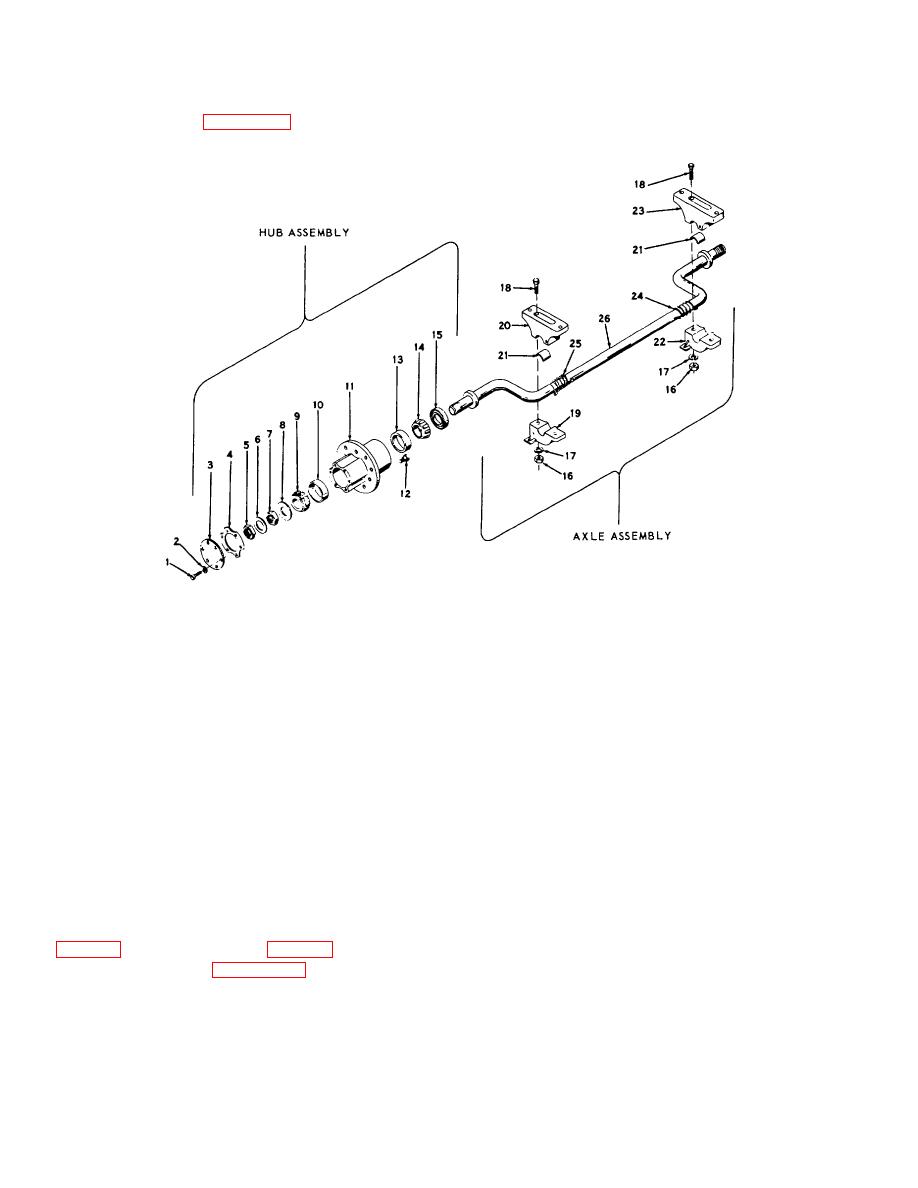

(5) Install new gasket and seal. Replace any

(2) Tighten nut (7) until the wheel bearing

defective part.

binds slightly when wheel is rotated, then back off nut

slowly until wheel rotates freely. Bend tang on washer

c. Reassembly and Installation.

(6) to lock the nut (7) in position.

(1) Refer to figure 4-15 and reassemble and

(3) Complete reassembly and installation.

install the seal, bearings, and hub assembly.

NOTE

DO NOT REMOVE BEARING CUPS (10,13) UNLESS DAMAGED OR WORN. WHEN INSTALLING

NEW CUPS, EXERCISE CARE NOT TO BUR OR DAMAGE CUP. DO NOT REMOVE BOLTS (12)

FROM HUB ASSEMBLY (11) UNLESS DAMAGED.

ME 4320-242-14/4-15

1.

Capscrew

10. Bearing cup

19. Bracket, top, rh

2.

Lockwasher

11. Hub

20. Bracket, base, rh

3.

Cap, grease

12. Bolt

21. Insert

4.

Gasket

13. Bearing cup

22. Bracket, top Ih

5.

Nut

14. Bearing cone

23. Bracket, base, lh

6.

Washer, nut lock

15. Seal

24. Spring, Ih

7.

Nut

16. Nut

25. Spring, rh

8.

Washer, wheel bearing

17. Washer

26. Axle

9..

Bearing cone

18. Screw

Figure 4-15. Hub and axle assembly, exploded view.

4-34. Axle Assembly

(1) Clean all parts with solvent.

Dry

thoroughly.

a. Removal and Disassembly.

(2) Inspect inserts for pitting, grooving, and

(1) Remove the wheel and tire assemblies

excessive wear. Inspect springs for cracks, breaks, and

loss of tension.

(2) Refer to figure 4-15 and remove and

(3) Inspect brackets and axle for cracks,

disassemble the axle assembly in the numerical

breaks and other damage. Replace damaged and

sequence indicated.

missing hardware. Replace a defective part.

b. Cleaning, Inspection, and Repair.

4-24

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |