|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

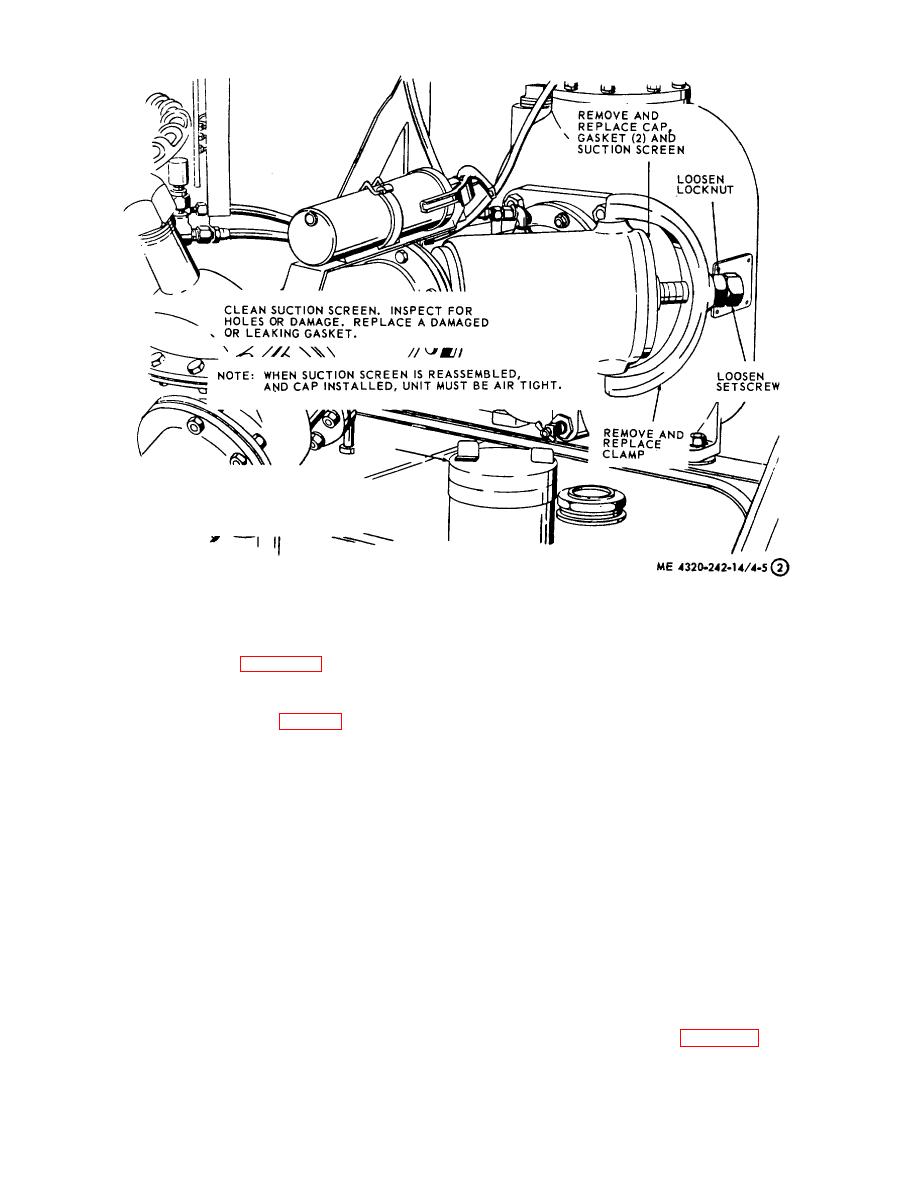

Figure 4-5. Suction screen, removal and installation. Serial numbers 419501 through

419959. (Sheet 2 of 2).

4-25. Air Eliminator Assembly

(4) Inspect all fittings and screws for damage.

Replace any defective parts as necessary.

air eliminator assembly.

(5) Discard the gasket and use a new gasket

for reassembly.

b. Disassembly.

(6) Inspect the valve and seat for wear,

(1) Remove hose (10, fig. 4-7), hose clamp

grooves, or ridges. Replace the valve and seat as an

(9), air venting valve (8), pipe coupling (7), pipe nipple

assembly if worn or damaged.

(6), pipe plug (4), and ball (3).

d. Reassembly.

(2) Remove nuts (20), lockwashers (21), and

capscrews (1 and 51.

(1) Assemble valve lever clip (12, fig. 3-11)

and seat (14) to cap (2).

(3) Remove cap assembly from discharge

elbow (19). Remove gasket (11).

(2) Assemble valve lever (16) to float

assembly (18) with screw (22).

(4) Remove valve retainer (17), pivot (13),

and valve (15).

(3) Install valve (15), valve retainer (17), and

pivot (13).

(5) Remove screw (22), separating valve

lever (161 and float assembly (18).

(4) Install a new gasket (11) and cap

assembly on discharge elbow (19).

(6)

Remove seat (14) and valve lever clip

(12) from cap (2).

(5) Install capscrews (1 and 5), lockwashers

(21), and nuts (20).

c. Cleaning and Inspection.

(6) Install ball (3), pipe plug (4), pipe nipple

(1) Clean all parts with cleaning solvent

(6), pipe coupling (7), air venting valve (8), hose (10),

PD680 and wipe dry with a clean, lintless cloth.

and hose clamp (9).

(2) Inspect the cover for cracks and breaks.

Replace a defective cover if necessary.

air eliminator assembly.

(3) Inspect the float assembly for holes and

cracks. Replace a defective float assembly.

4-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |