|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4320-234-34

(3) After assembly, when using either new or

It is easier to disassemble the pump parts from the

engine than it is to remove the entire pump assembly

used parts, recheck the clearance; it must be 0.010 to

before starting disassembly. If the pump is mounted on

0.020 inch (0.025 to 0.050 cm). Check the impeller

the engine, disassemble it per paragraph 5-2 for seal

shaft for free rotation. It must turn freely without

replacement. Then remove the bearing housing from the

catching or binding. If binding is evident, disassemble

engine and disassemble it. If the pump assembly was

removed from the engine per paragraph 2-9, proceed as

the pump and correct the condition.

directed below.

(4) Install the assembled pump and bearing

housing onto the engine and chassis (para 2-9).

(1) Remove

the assembled pump

and

bearing housing from the engine and chassis (para 2-9).

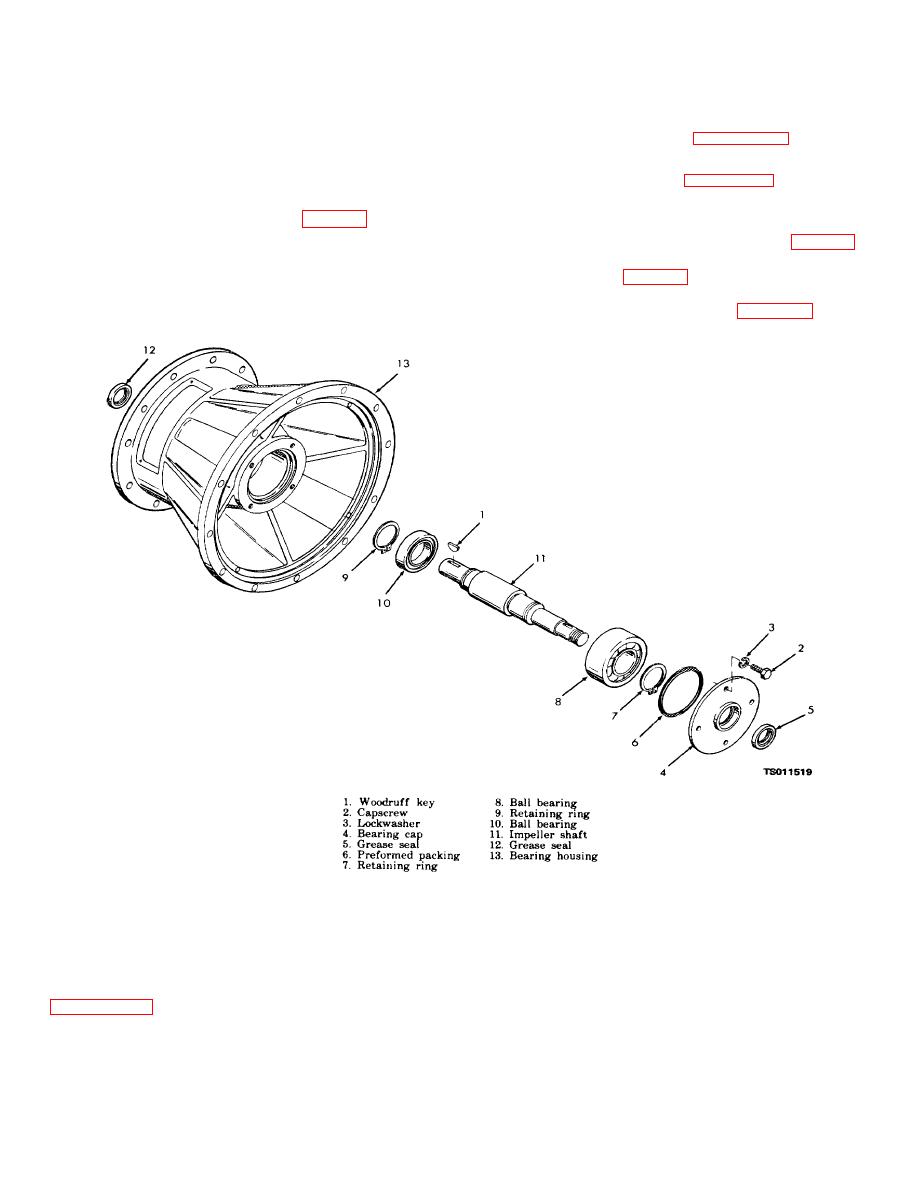

5-4. Bearing Housing

(2) Disassemble the centrifugal pump from

a. Disassembly.

the bearing housing (para 5-3).

(3) Disassemble

the

bearing

housing

NOTE

assembly in the sequence indicated in figure 5-2.

Figure 5-2. Bearing housing, exploded view.

b. Cleaning and Inspection.

Clean all parts in a well-ventilated area.

(1) Discard and replace all seals, gaskets,

Avoid inhalation of solvent fumes and

and packings.

prolonged exposure of skin to cleaning

(2) Clean the ball bearings as directed in

solvent. Wash exposed skin thoroughly.

Dry cleaning solvent (Fed. Spec. P-D-680)

used to clean parts is potentially dangerous

WARNING

to personnel and property. Do not use

5-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |