|

|||

|

|

|||

|

Page Title:

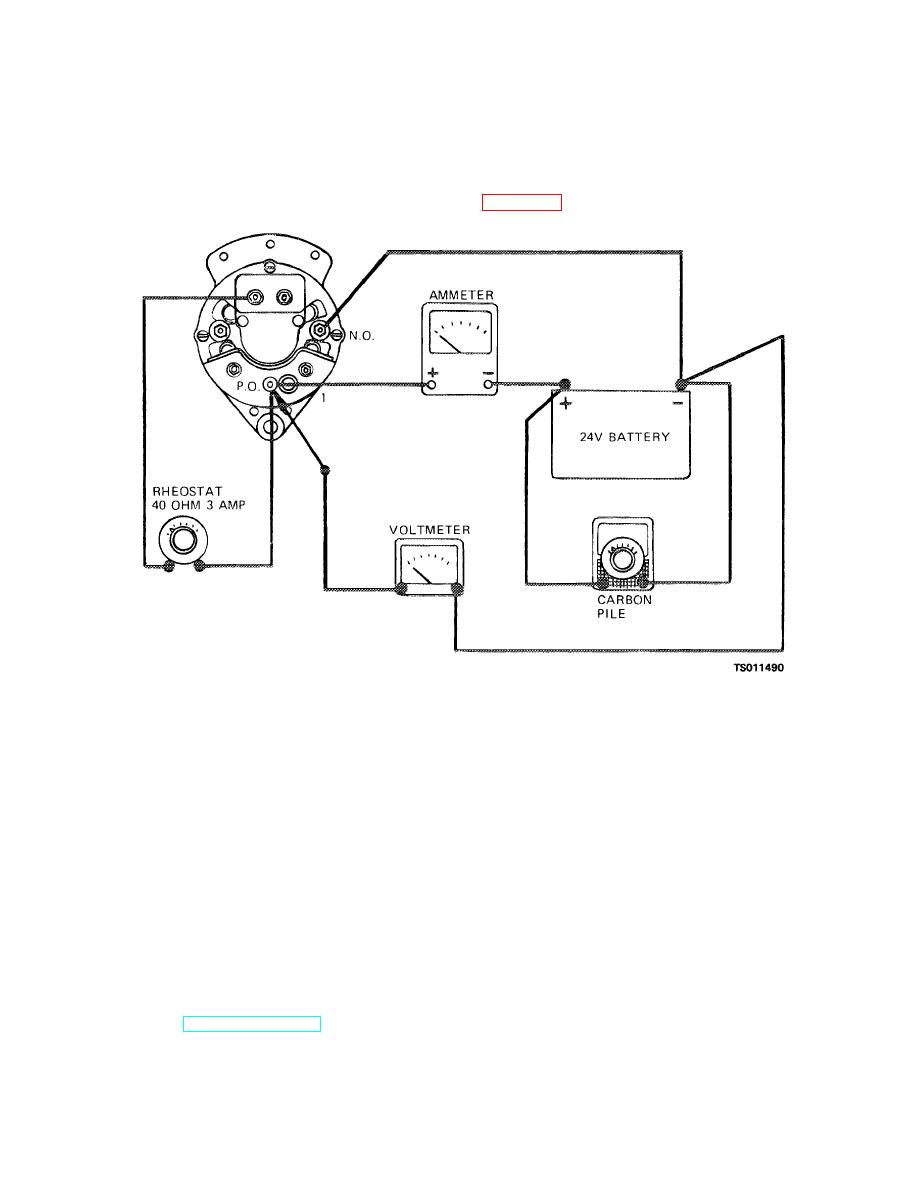

Figure 3-11. Alternator bench test circuit. |

|

||

| ||||||||||

|

|

TM 5-4320-234-34

(1) Mount the alternator in a test fixture

Secure the diode with nuts (24).

capable of providing 3000 rpm.

g.

Bench Test.

The following test will

(2) Connect fixture circuit leads and

determine the current producing capability of the

instruments to the alternator terminals as shown in

repaired alternator.

Figure 3-11. Alternator bench test circuit.

(3) With the carbon pile turned off to avoid

If you have determined by testing (TM 5-4320-

discharging the battery, set the field rheostat in

234-12, para 4-39) that the voltage regulator should be

maximum resistance position.

adjusted to suit your operating conditions, proceed

according to either of the following methods.

(4) Start the test fixture, and operate at

1500 rpm for a few minutes to normalize operating

a.

You can change the voltage approximately

temperature.

0.6 volt higher or lower by using a metal strap provided

on the underside of the regulator case. Raise the

(5) Increase the alternator speed to 3000

voltage 0.6 volt by placing the metal strap across the

rpm and, at the same time, apply the carbon pile load to

terminals marked HI. Secure strap with the terminal

the battery to keep the charging voltage below 28.0

nuts. Lower the voltage 0.6 volt by placing the metal

volts. At 3000 rpm, the alternator should provide a

strap across the terminals marked LO.

minimum current output of 28 amperes.

b.

If the step adjustment described above did

(6) The charging voltage can be adjusted

not give the exact system voltage you desire, follow this

by the voltage regulator when the alternator is installed

procedure:

on the engine.

(1) With the engine off, connect a

h.

voltmeter to the battery and connect an ammeter in

procedures given in TM 5-4320-234-12, para 4-38.

series with output of the alternator as shown in figure 3-

12.

3-18. Voltage Regulator Adjustment

3-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |