|

|||

|

|

|||

|

Page Title:

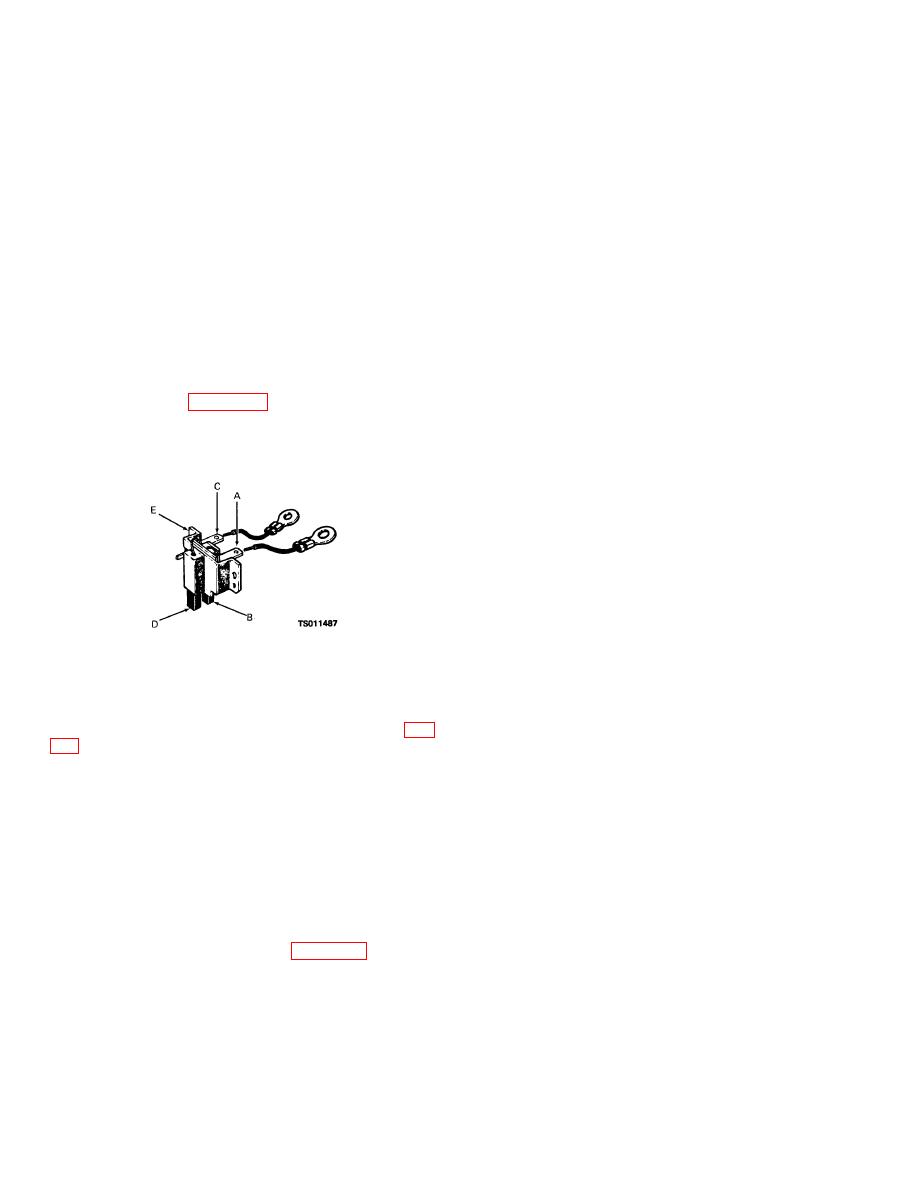

Figure 3-8. Alternator brush assembly, showing continuity paths. |

|

||

| ||||||||||

|

|

TM 5-4320-234-34

(2) Remove the isolation diode assembly

(2) Remove the two terminal screws (7),

(26). When removing the diode assemblies, note the

nuts (8), insulating washers (9), leads (12), washers

positions of the insulating sleeves and washers to

(11), and bushings (10) from the brush cover.

ensure reassembly in proper positions.

(3) Remove the two screws (13) that

(3) Remove the square nuts (28) and

secure the insulator (14) and brush assembly (15) to the

through bolts (20) that secure the front housing (32) to

alternator; remove the brush assembly with the attached

the rear housing (41).

electrical leads (12).

(4) Using a small bladed screwdriver, pry

(4) Inspect the brush assembly for cracks,

at several points around the stator to remove the

signs of over-heating, and distortion. Check that the

assembled rotor and front housing. Do not insert the

brushes slide freely in the brushholders and that the

screwdriver blade more than 1/16 inch, or damage to

brush springs provide sufficient brush tension. Inspect

the stator windings may occur while you are separating

the brushes for cracks, oil saturation, and wear. If you

the front housing from the stator.

find that the brushes are worn to less than 3/16 inch

(0.468 cm), oil soaked, or cracked, replace the brush

(5) Clamp the front housing lightly in a vise

assembly.

and, using long nose pliers, reach through the front

housing (32) to compress the ears of the bearing

(5) If the brush assembly passes your

retainer (30) and lift it free of its recessed seat.

visual inspection, check the electrical condition of the

assembly. Refer to figure 3-8. Check that continuity

(6) With the bearing retainer free of the

exists between points A and B and between points C

recess, you can remove the assembled rotor and

and D, but that no continuity exists between point E and

bearings by tapping the end of the rotor shaft on a block

points A or C.

of wood while holding the housing.

(7) Place the assembled stator (33) and

rear housing (41) on a clean, smooth working surface

that is free of metal chips. Remove the lock nuts (34)

and insulating washers (35) that secure the studs of the

diode assemblies (36 and 37) to the rear housing (41).

Carefully push the studs out of the housing and separate

the assembled diode assemblies and stator (33) from

the rear housing.

(8) Do not disassemble the rotor unless the

bearings or slip rings are damaged and must be

Figure 3-8. Alternator brush assembly, showing

replaced. If you must remove the bearings and slip

continuity paths.

rings, proceed as follows:

(6) Use a new brush assembly if the

(a) Use a bearing puller to remove

inspection indicates faults.

the front bearing from the rotor shaft.

(7) Position the brush assembly (15, fig.

(b) Remove any sealant retaining the

rotor winding leads to the slip ring.

machine screws (13).

(8) Connect the electrical leads (12) from

slip ring terminals. Unwind the leads from the terminals,

the brush assembly to the brush cover (5) with the

taking care you do not bend or stress leads excessively.

terminal screws (7), nuts (8), insulating washers (9), and

(d) Remove the screw (42) from end

washers (11). Make sure you have the bushings (10) in

of shaft. Thread a 1/4-28 x 1-1/4-inch long screw into

place.

the slip ring hub; this process will back the slip ring

(9) Position the brush cover (5) on the

assembly (44) off the shaft.

alternator; secure with two assembled washer screws

(e) Use a bearing puller to remove

(4).

the rear bearing (45), taking care you do not damage the

c.

rotor leads.

following the sequence indicated in figure 3-7. Note the

d.

Cleaning and Inspection.

following:

(1)

Discard and replace gaskets.

(1) To remove the pulley (18), wrap the

alternator drive belt around the pulley and clamp it in a

WARNING

vise so that the belt protects pulley edges. Strike the

Clean all parts in a well-ventilated area.

end of the rotor shaft with a soft mallet or plastic

Avoid inhalation of solvent

hammer to jar loose the pulley.

3-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |