|

| |

APPENDIX A

METER CLEARANCE GUIDE

CLEARANCE GUIDE

The clearances listed herein should be used as a guide in determining whether or not components need to be

repaired or replaced. Also, they should be considered as average. This means for instance, that if a nominal clearance

is .004, for manufacturing tolerances a spread from .003 to .005 is permissible. Because of this, it is possible when

checking with feeler gauges, to find at one point .003 clearance, while at another point along the same surface, the

clearance may be .005 or even .006. However, from a performance standpoint, that portion which is .003 will generally

cancel out the effect of the .005 or .006 ant average out at the nominal .004 desired. At no point should a clearance

exceed 50% of the listed maximum.

From this it should be clear that a part need not be replaced or repaired just because clearances at some point

may slightly exceed the listed maximum.

The ability of the meter to obtain acceptable repeatability and linearity for the particular operating conditions, such

as flow rate, viscosity, lubricity, abrasive contaminants, and intermittent or continuous duty, should be considered a

better guide rather than clearances alone.

For viscosities above 1000 SSU and/or temperatures above 150° F., consult the factory.

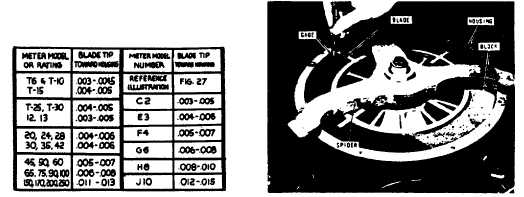

BLADE TO HOUSING CLEIRINCE

With the Blade held toward the Housing, these clearances should be maintained between the Measuring Chamber and

the full length of the edge of the Blade.

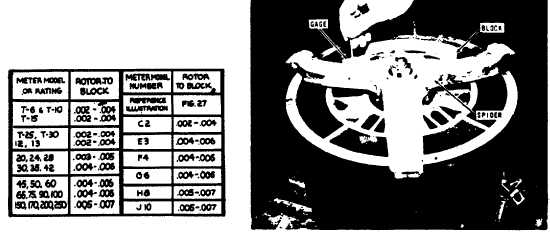

ROTOR TO BLOCK CLEARANCE

These clearances between Rotor and Block should be maintained the full length of the Rotor.

SPECIAL TOOLS REQUIRED

1. SPIDER

2. FEELER GAUGE

SPECIAL TOOLS REQUIRED

1. SPIDER

2. FEELER GAUGE

A9-40

|