|

| |

APPENDIX A

Calibration of Meters with Manual and ATC Calibrators

For the purpose of adjustment, some Smith meters

are equipped with a calibrator utilizing two overriding

clutches and an eccentric. By adjusting the amount of

eccentricity the calibrator can be made to vary the drive

ratio between the meter and the register by a maximum

total of 11 per cent.

This calibrating means is used for adjusting for

manufacturing

variations,

variations

in

operating

conditions, differences in viscosity of product metered,

variations in testing methods and testing equipment as

well

as

for

providing

automatic

temperature

compensation.

The nature of the device is such that a correction

impulse is imparted to the calibrator output shaft once

during each revolution. The correction impulse causes

a momentary acceleration of the register which will

result in errors and erratic tests if not taken into account.

It is important when calibrating a meter that the

volume of the calibrated prover be a multiple of the

increment of correction of the meter. For example, a

prover for 5:1 gallon geared meters should be 200, 205

or 210 gallon capacity and not 203 or 207. For 1:1

barrel geared meters it is essential that the prover be

calibrated in even 42 gallon barrels.

The reason for the above is evident as each test run

must contain the same number of correction impulses in

order to be absolutely accurate. If the test is started

with the meter register at zero, the register at the end of

the test run should show a quantity divisible by the

number of gallons or barrels delivered for each

revolution of the calibrator, or each correction impulse.

The magnitude of the meter correction is in the

order of 5 or 6 per cent of the volume of meter thruput

per correction input cycle. On a standard 5:1 gallon

geared meter this would be S or 6 per cent of 5 gallons

and on a 1:1 barrel geared meter it would amount to 5 or

6 per cent of 42 gallons. The type of register used is not

necessarily an indication of meter correction frequency,

as a gallon geared meter may be equipped with a

register geared to read in barrels.

It is therefore desirable to have the prover tank of a

volume which conforms to even increments of full

barrels as well as increments of 5 gallons, as for

example, 30 barrels or 1260 gallons. A prover of this

size makes it possible to test either a gallon geared

meter or a barrel geared meter. By starting and

stopping the meter on an even barrel or five gallon

increment as the case may be and reading the error on

the prover scale, the error due to meter correction

impulse is entirely eliminated.

Many meters with gallon gearing are equipped with

barrel registers and it may be necessary to test these

meters into a barrel calibrated prover. Further, the

prover may be of an odd size, barrels and fractions of

barrels.

Take as an example a prover of 29.3 barrel capacity

being used to test a meter with gallon gearing (5 gallons

per revolution) with a register reading in barrels. The

register will be assembled with 8.4:1 gear ratio.

In a case of this kind the meter calibrator impulse

error can be avoided by following the procedure outlined

below.

Determine the number of gallons contained in the

prover 29.3 x 42 = 1230.6 gallons. Reduce this to the

nearest number divisible by 5 or 1230. Now consider

the volume of the prover 1230 gallons or 29.285 barrels

instead of 29.3 barrels. Make a test run stopping the

meter at exactly 29.285 barrels thereby completing the

full number of correction cycles. Read the error on the

prover scale.

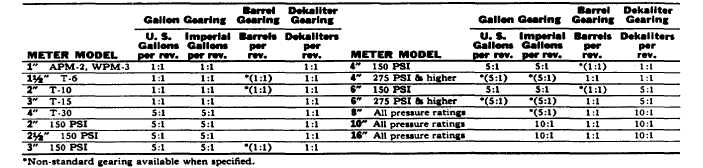

METER GEARING--Metered throughput per revolution of meter output shaft.

A9-37

|