|

| |

APPENDIX A

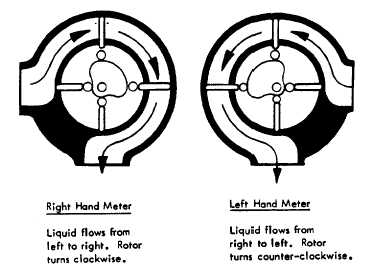

FIG. 12.

d.

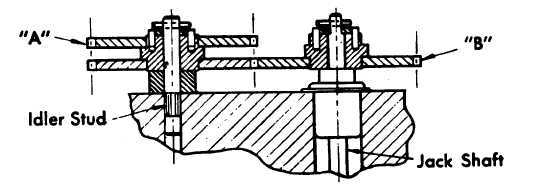

The Meter is reversed simply by interchanging

the Jack Shaft Gear "B", and the Intermediate

Gear "A". It will be observed that the washers

on these gears are not the same type and

consequently must remain on their respective

shafts.

e.

After the gears are interchanged, replace the

washers and cotter pins. It may be necessary to

lift up the Jack Shaft with pliers before the cotter

pin can be inserted, as this Shaft drops slightly

when the cotter pin is removed.

f.

When replacing the Counter Adapter Assembly,

line up the drive gears between the calibrator

and the Meter Gear so that they engage

properly, before tightening the Counter Adapter

Screws.

MAINTENANCE

The Smith Rotary Positive Displacement Meter requires

a minimum of maintenance.

The calibrator should be kept well lubricated by applying

S.A.E. 10 oil or lighter, such as ordinary household oil,

through the oil cup directly below the counter.

Meters should be drained of sediment periodically.

If meter is to be stored or idle for any length of time,

flush with light lubricating oil.

FIG. 13.

A9-25

|