|

| |

TM 10-8110-203-12&P

4-4. SERVICE UPON RECEIPT - continued.

e. Position drum for access to other closure plate and flatten drum body to remove air from drum.

f. Repeat steps c and d at other end of drum.

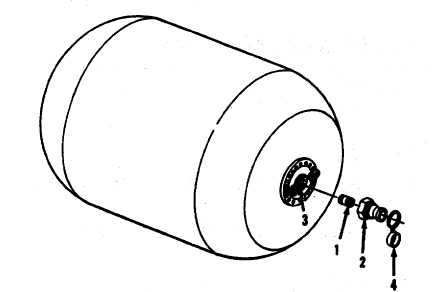

g. Place protective caps (4) on adapters (2).

Figure 4-1. lnstalling Pipe Nipples and Adapters

Section III. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

There are no unit preventive maintenance checks and services for the 500 gallon drum.

Section IV. UNIT TROUBLESHOOTING PROCEDURES

4-5. INTRODUCTION.

a. This section contains troubleshooting information for locating and correcting most of the operation troubles

which may develop in the drum. Each malfunction is followed by a test or inspection which will help you to determine

corrective actions to take.

b. This manual cannot list all malfunctions that may occur, nor all tests or inspection and corrective actions. If a

malfunction is not listed or is not corrected by listed corrective actions. notify your supervisor.

c. Table 4-1 lists common malfunctions which you may find during the operation or maintenance of the drum

and its components. You should perform the tests/inspections and corrective actions in the order listed.

4-2

|