|

|||

|

|

|||

|

Page Title:

CHAPTER 5. CAN, WATER, MILITARY; PLASTIC; 5-GALLON |

|

||

| ||||||||||

|

|

TM 10-7200-200-13

CHAPTER 5

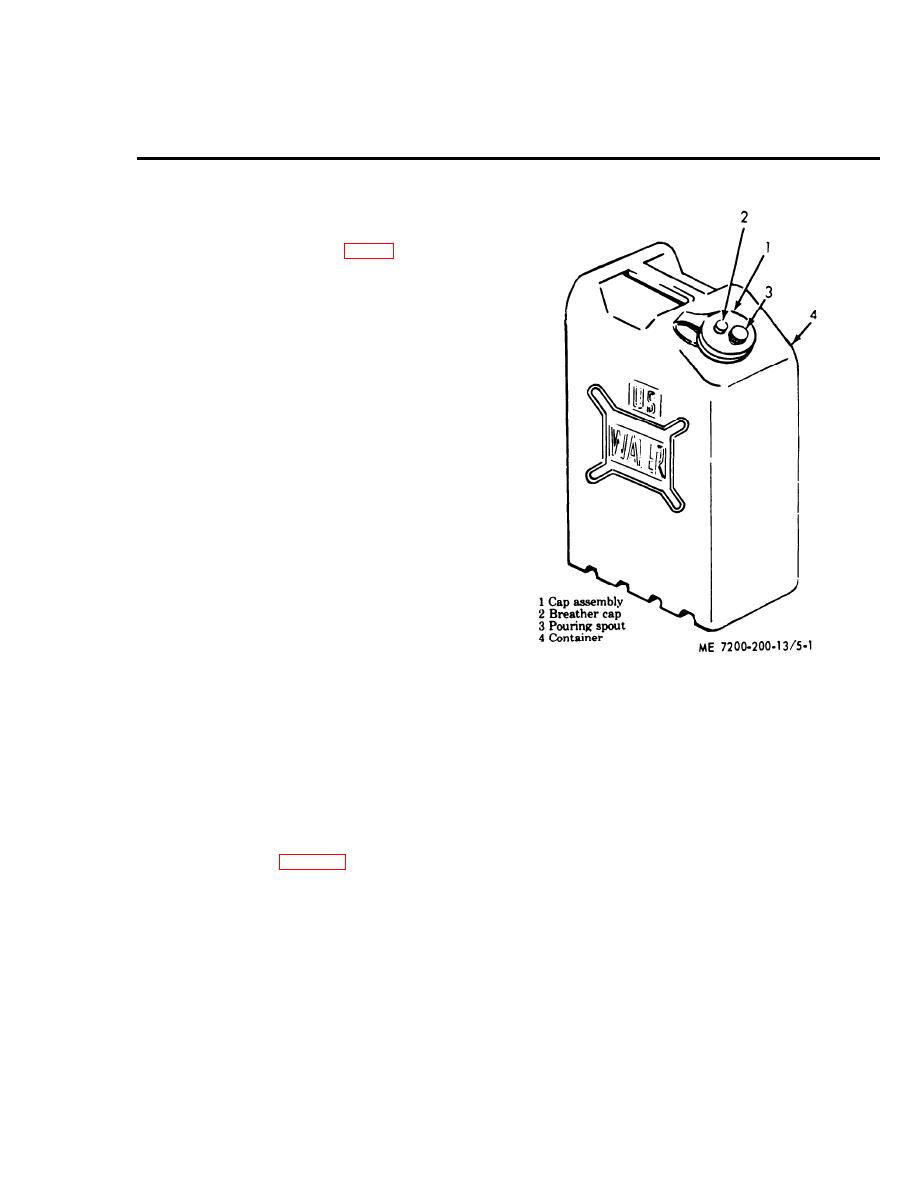

CAN, WATER, MILITARY; PLASTIC; 5-GALLON

Section I. DESCRIPTION AND TABULATED DATA

5-1. Description

The 5-gallon plastic water can (fig. 5-1) is covered by

specification MIL-C43613 (1). It consists of the body

and the cap. The plastic body is constructed of

highdensity linear virgin polyethylene conforming

to class C, grade 2 of MI L-P-22748, and the

requirements of Federal, Food, Drug, and Cosmetic

Act. The cap assembly is of low density virgin

polyethylene conforming to type III, class L, grade 8

of LP-390, except that the melt index has a

maximum of 4.0 instead of 0.4. The cans are used for

transporting water.

5-2 Tabulated Data

a. Dimensions

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 5/8 inches

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 7/16 inches

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 inches

b. Capacities.

Liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.05 gal.

Cubage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 cu. ft.

Figure 5-1. Water can, plastic, 5-gallon.

Section Il. OPERATOR/CREW MAINTENANCE

5-3. Lubrication Instructions

plastic can with a sanitizing chemical, but when it is

required, the chemical must be specified or approved

The five gallon plastic can does not require lubrica-

by the Surgeon General. Use this procedure to clean

tion.

the plastic water can.

5-4. Preventive Maintenance Services

(1) Clean the exterior of cans including the

closure assembly. Use a hot solution of the detergent

The necessary preventive maintenance checks and

compound, P-D410, FSN 7930-2814731, and a cloth,

services to be performed at regularly scheduled

sponge, or fiber brush.

intervals are listed in table 5-1.

(2) Clean the interior of the cans with a hot

5-5. Cleaning, Inspection and Repair

solution of the synthetic detergent P-D-410 at a

concentration of one ounce per gallon, using a cloth,

a. Inspection

sponge, or fiber brush, to reach all areas of the can.

(1) Inspect the cans for cuts, tears, burns, cracks,

Do not use scouring powders, steel wool, metal

and other damage. Make sure the can is free from

sponge, or other abrasive materials which may

leaks.

scratch the surface and make subsequent cleaning

(2) Inspect the interior for cleanliness and for the

difficult.

presence of contamination.

(3) Rinse cans in clear hot water, turn upside

b. Cleaning. Plastic water cans should not be put on

down, and allow to air dry. Water hotter than 180F

a scheduled basis of cleaning, but should be cleaned

may cause the cans to lose shape.

when dirty. There is usually no reason to treat the

Change 1 5-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |