|

| |

TM 10-6630-240-12&P

TM 01461B-12&P/1

g.

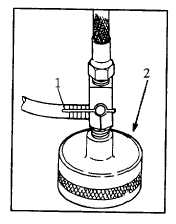

Flush the inlet hose by turning the three-way valve (1) to the FLUSH position: the valve arm is horizontal to the

base of the valve (2). Pass at least 3.2 quarts (3 or more liters) into a 5 gallon receptacle to remove contaminants from

the inlet valve. (figure 2-6)

Figure 2-6

h.

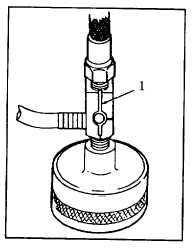

Take a sample by holding the sampler in an upright (vertical) position, turn the threeway valve (1) to the TEST

position. Allow no more than 1 liter (1.0 qt) to flow through the monitor. Record the sample volume for reporting. When

the collection is completed turn the three-way valve to the off position before turning off the system pump. Remove the

sampler from the system fitting and replace the protective cap and plug. (figure 2-7)

CAUTION

Some pumping systems (e.g. aircraft refuelers) develop a vacuum when closed which can

cause backflow and rupture the monitor filter, rendering the test ineffective.

Figure 2-7

i.

Disconnect the bypass hose (1) from the side of the sampler and unscrew the sampler base (2) from the sampler

cover. Hold the sampler in an upright position and remove the monitor (3). (figure 2-8)

2-6

|