|

| |

TM 10-4930-245-13&P

4-2.

SPECIAL TOOLS, TMDE, AND SUPPORT EQUIPMENT.

Special tools, TMDE and support equipment are listed in the Maintenance Allocation Chart, Appendix B, and the Repair

Parts and Special Tools List (RPSTL), Appendix C of this TM.

4-3.

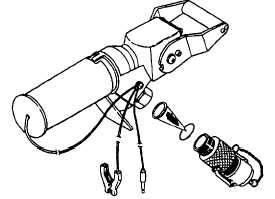

REPAIR PARTS.

Repair parts are listed and illustrated in Appendix C of this manual.

Section II. UNIT PREVENTIVE MAINTENANCE CHECKS AND SERVICES

4-4.

GENERAL.

To ensure that the CCR Nozzle is ready for use at all times, it must be inspected systematically so that defects may be

discovered and corrected before they result in serious damage or equipment failure. The necessary preventive

maintenance checks and services to be performed are listed and described in Table 4-1. Defects discovered during

operation of the unit should be corrected as soon as possible. All deficiencies and shortcomings will be recorded,

together with the corrective actions taken, on DA Form 2404 (Equipment Inspection and Maintenance Worksheet) at the

earliest possible opportunity.

Table 4-1. Unit Preventive Maintenance Checks and Services.

Item

No.

Item to be

Inspected

Interval

Procedures:

Check for and have

Repaired as Necessary

For Readiness Reporting

Equipment is Not

Ready/Available if:

1

Strainer

Every

2 weeks

Check for foreign matter and holes.

Clean and/or replace as required (para.

4-10).

Holes in strainer.

4-2

|