|

| |

TM 10-4320-342-24

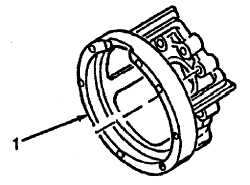

4-4. STARTER-GENERATOR REPAIR - continued

d.

REPAIR.

(1)

Replace any damaged parts found during inspection.

Refer to Figure 4-12.

(2)

Repair end bell assembly as follows:

(a)

Coat any chipped area on end bell assembly (1) with red insulating enamel.

(b)

Place end bell assembly (1) in an oven for one hour at the temperature of 150F (66C). Remove and let

cool to ambient (room)temperature.

Figure 4-12. End Bell Assembly Repair

Refer to Figure 4-13.

(3)

Repair armature (1) as follows:

(a)

Perform measurements A and B to obtain diameter of bearing journals on shaft (2). Replace armature if

diameter is not within 0.6691 to 0.6694 inches.

(b)

Perform measurement C to obtain diameter of commutator (3). Replace armature (1) if commutator

diameter is less than 1.960 inches.

(c)

Install armature (1) in a lathe and refinish commutator (3). Remove only the material necessary to clean

and true-up commutator surface. Replace armature if commutator diameter must be refinished to less than

1.960 inches.

NOTE

If capabilities (tools and facilities) exist, perform bar concentricity of commutator

on armature. If not, replace armature.

(d)

Place measuring tool on commutator bar (3) and rotate armature (1) slowly for one complete turn to obtain

bar concentricity. Bar concentricity must be within 0.0002 inch.

4-15

|