|

| |

TM 10-4320-324-14

b. Repair.

(1) Rework cylinder liner seating on crankcase as

follows:

(a) Clean seating area and remove paint

residues.

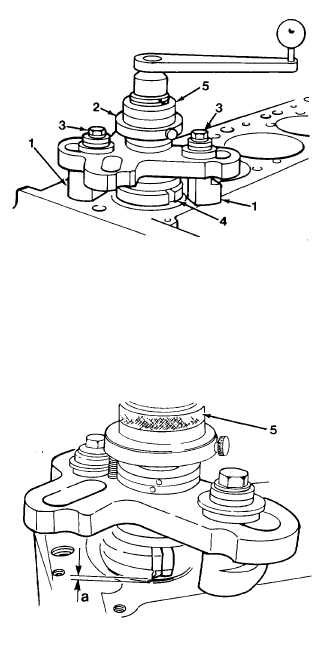

(b) Place support brackets (1) in position, mount

turning fixture (2), and tighten retaining bolts

(3) in such a manner that turning fixture is

still movable.

(c) Center refacing device and tighten bolts (3).

(d) Withdraw centering finger and slide tool

holder (4) out to diameter of cylinder seating

face.

CAUTION

DO NOT turn spindle counterclockwise when

reworking surface or refacing device will be broken.

Adjust feed carefully. A full turn (3600) of the

knurled nut feeds the tool holder inch (1.5 mm).

(e) By means of knurled nut (5), turn spindle of

turning device clockwise and adjust tool

holder (4) to face to be reworked.

(f) Move the tool holder (4) towards the middle

of the bore.

(g) Using knurled nut (5) set the tool over and

slightly beyond distance "a" to permit

satisfactory refacing.

6-49

|