|

| |

TM 10-4320-324-14

(13) Inspect valves for cracks and pits. Replace as

required. Reface valves if required and inspect

to the tolerances specified in Appendix F,

Table F-1.

(14) Inspect cylinder head for external damage or

cracks. Replace cylinder head if damaged or

cracked.

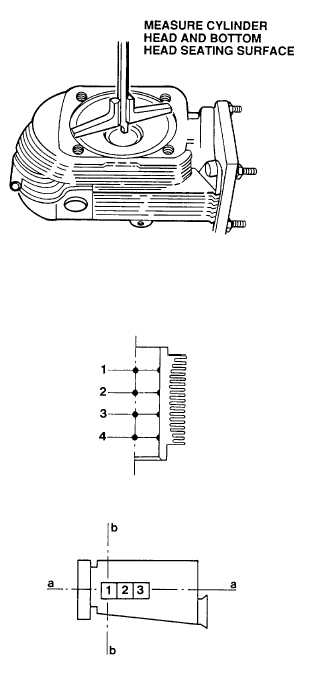

(15) Check cylinder head seating surface. It must

be flat and square. Slight damage to seating

surface can be removed by grinding cylinder

head on cylinder with fine abrasive paste.

(16) If cylinder head seating surface is more

severely damaged, recut with plate mill.

(17) After reworking, measure clearance between

cylinder head bottom and cylinder head seating

surface. The measured value may not be

lower than 0.23 in. (5.8 mm).

(18) Insert valve seat and measure distance from

crown of valve to cylinder head seating

surface. If distance exceeds specifications on

either valve (Table 6-1), seat must be

replaced.

(19) Check clearance of valve stems in guides of

both valves. If it exceeds 0.0016 in. (0.04

mm) inlet valve, or 0.0024 in. (0.06 mm)

exhaust valve, replace guides.

(20) Inspect cylinder liner as follows. If necessary,

replace complete with piston.

(a) Set dial gauge to 3.937 inches (100 mm).

(b) Measure cylinder bore at levels 1 to 4 of

engine center line "a" as well as crossline

"b".

(c) Compare readings with above dimensions.

If not within plus 0.0079 inch (0.2 mm),

replace parts concerned.

6-19

|