|

| |

TM 10-4320-307-10

Table 2-2. Operator/Crew Preventive Maintenance Checks and Services - (Cont)

Item

Location

Not Fully

No.

Interval

Item to

Procedure

Mission Capable

Check/Service

if:

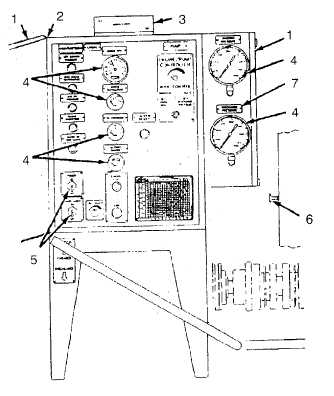

55

Weekly

Control Pan-

Visually inspect doors (1) and hinges (2) for security of

Damage to the

el Assembly

attachment.

assembly indi-

Visually inspect for cracks in welds around the control panel

cates internal

assembly.

components are

Check work light (3) for operation and security of attachment

damaged.

Inspect gauges (4) for broken glass, legibility or other damage.

Clean gauge faces by wiping with a damp cloth.

Inspect switches (5) for damage or loose mountings. Check

switches for smooth operation.

Inspect ether start knob (6) for general condition.

Inspect for legibility of all markings and security of all descrip-

tive plates (7).

56

Weekly

Wiring Con-

Visually inspect the interior of the control panel assembly for

Category Class

trol Panel

security of all connectors and wiring, frayed or worn oil pres-

III leakage, arc-

and Instru-

sure electrical wire, leaking suction hose assembly, frayed or

ing, or evidence

ment Hoses

worn tachometer cable, and damaged or broken cable ties.

of arcing is

Visually inspect all main wiring harnesses on the engine for

found. Bare or

secure attachment, or broken or frayed insulation or wires.

broken wires are

found.

2-49

|