|

| |

T M 1 0 - 3 8 3 5 - 2 1 9 - 14

Table 2-1. Preventive Maintenance Checks and Services (PMCS) (cont).

I n t e r v a l

Item

No.

1

0

11

B - Before Operation

D - During Operation

B

D

A

Item to be inspected

P r o c e d u re

Chain hoist

a. Inspect chain (27) for excessive wear

or stretch, bent or twisted links,

defective welds, nicks and gouges.

Notify next higher level of maintenance

of damaged parts.

b. Inspect ratchet (28) for breaks, cracks

or distortions. Notify next higher level

of maintenance of damaged parts.

c. Inspect throat opening of hooks (29).

If opening is more than 15 percent in

excess of normal, more than a 10

degree twist from the plane of the

unbent hook, or wear exceeds 10

percent of the original dimensions,

notify next higher level of maintenance.

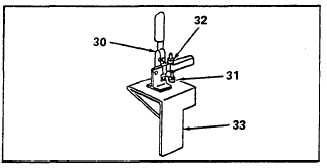

Hose Retaining Bracket

a.

b.

c.

Inspect for bent, broken or cracked

clamp (30). Replace assembly if

damage noted.

Inspect for missing or damaged screw

(31) or nut (32). Notify next higher

level of maintenance.

Inspect for bent, cracked or distorted

bracket (33). Replace assembly if

damage noted.

A - After Operation

Equipment is not

ready/available if:

Chain is broken, excessively

worn, has broken welds, or

is nicked and gouged.

Ratchet is broken, cracked,

o r d i s t o r t e d.

Hooks are distorted beyond

limits, cracked, damaged,

or missing.

Clamp is bent, broken or

distorted.

Screw or nut is missing,

loose, or damaged.

Bracket is bent, cracked or

distorted.

2 - 1 0

|