|

| |

T M 1 0 - 3 8 3 5 - 2 1 9 - 1 4

I n t e r v a l

Item

No.

2

Table 2-1. Preventive Maintenance Checks and Services (PMCS) (cont).

B - Before Operation

D - During Operation

B

D

A

Item to be inspected

P r o c e d u re

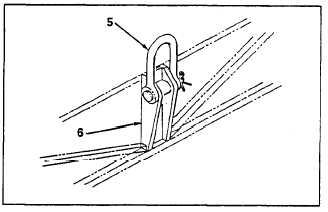

Sling Assembly (cent)

e.

f.

W A R N I N G

Broken wire rope strands are a

hazard, and can cause serious

punctures and cuts. Take care

when handling and inspecting

cables.

Inspect wire rope for broken or

worn outside wires, reduction of

rope diameter below nominal

value, corroded, broken, or

frayed wires at end connections.

Check for severe kinking,

crushing, cutting or unstranding.

Check for worn, broken or missing

cable thimbles at rings and eyes and

loose or missing cable clips. Notify

higher level of maintenance of

damaged parts.

Flaking Box Assembly

a. Check all accessible frame seam welds

for cracks or separated metal.

Notify next higher level of

maintenance of damaged parts.

A - After Operation

Equipment is not

ready/available if:

Any reduction in diameter,

excessive corrosion,

any broken, frayed wires,

wire is kinked, broken

or crushed.

Cable trimbles worn,

broken or missing.

Cable clips are loose

or missing.

Seam weld is cracked

or metal separated.

2 -4

|