|

| |

TM 55-2915-335-30&P

Table 2-2. Maintenance Troubleshooting-Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

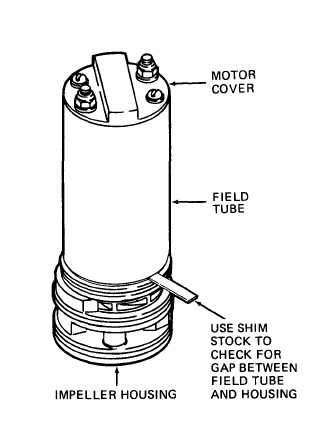

6. MOTOR DRAWS HIGH CURRENT

Step 1. Check pump cartridge assembly for

binding. The field tube may be cocked on im-

peller housing. This would cause bearings to

bind on the armature shaft. Use a thin piece of

shim stock or fine paper to check for gaps. If

no gaps are found, proceed to Step 2.

If a gap is found, the motor was

not assembled properly. Motor

bearings are probably damaged.

Remove armature, field tube,

and impeller from impeller

housing (paragraphs 2-18 and

2-19). Inspect inside diameters

of motor bearings for chipping

or cracks per instructions and

illustrations in paragraphs 2-16

and 2-22. Measure bearing

bore diameters per inspection

procedure. Replace bearings

if damaged or not within

dimensions.

2-16

|