|

| |

TM 55-2915-335-30&P

Table 2-2. Maintenance Troubleshooting - Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

5. PUMP STALLS UNDER LOAD (Cont)

Step 2. Check for commutator arcing.

Remove armature per paragraph 2-18. Check commutators for

brown or gray buildup. Buildup is the result of bacteria in fuel. If buildup is seen, use 500 or 600 grit, wet or

dry, emery paper to clean commutator (paragraph 2-18). Inspect commutator surfaces for pitting. If com-

mutators are not pitted, proceed to Step 3.

If commutators are pitted, check other motor parts for pitting. Pitted components cannot be

repaired and must be replaced.

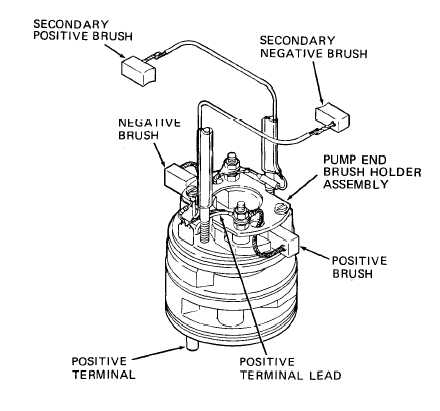

Step 3. Check for worn or defective wiring. To check for incorrect wiring, compare wiring with illustration.

Check terminals on pump-end brush holder assembly for loose or broken connections. Inspect for burned or

worn leads. If wire and connections are good, proceed to Step 4.

Inspect and replace wiring and connectors per instructions and illustrations in paragraph

2-23.

Step 4. If brushes and wiring are good, armature is defective.

Inspect armature per instructions and illustrations in paragraph 2-18. If defective, replace

armature.

2-15

|