|

| |

TM 5-4320-306-24

4-13.

REPLACE/REPAIR CRANKCASE ASSEMBLY (Continued)

21

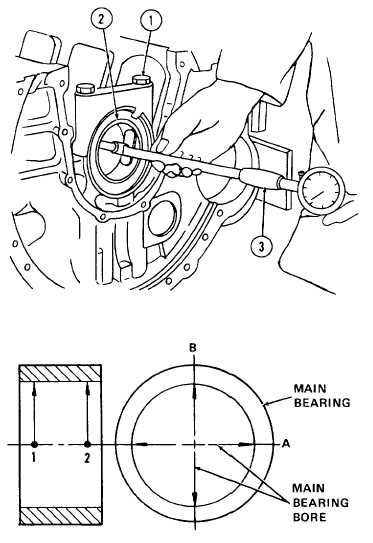

Check main bearing bore

a.

If a main bearing cap bore is within or

just slightly outside tolerance limits or if

a new main bearing cap is being used,

loosen bolts (1) alternately and evenly

far enough to be able to install main

bearings (2). Make sure matchmarks

are correctly alined if new bearings are

not being installed. Make sure oil

passage is installed in upper bearing

cap. If new caps or bearings are being

installed, match-mark them. Tighten

and retighten bolts as in step 20b.

b.

Measure

main

bearing

bore

with

micrometer (3) at points 1 and 2 and

along axes A and B. Bore should

measure

2.8757

to

2.8772

inches

(73.042 to 73.081 mm). If measurement

is not within these tolerance limits, main

bearing must be replaced.

c.

If measurements were taken with new

main bearings and a main bearing cap

that was only slightly outside tolerance

limits, the acceptable main bearing

tolerance limits may be increased to

2.8749 to 2.878 inches (73.022 to

73.101 mm). If measurements are still

not within these extended tolerance

limits, the main bearing caps and

crankcase must be replaced.

22

Check radial clearance.

a

Replacement of main bearings depends on the diameter of the crankshaft center bearing journal. Measure

diameter and determine radial clearance by subtracting journal diameter from bearing bore. Clearance

should be 0.0020 to 0.0043 inch (0.052 to 0.110 mm). Maximum allowable clearance is 0.0118 inch (0 3

mm),

b.

If radial clearance is not within these tolerance limits, recheck main bearings, main bearing cap, and/or

crankshaft. Replace components in that order until clearance is within tolerance limits.

23

Check side clearance.

a.

Measure width of crankshaft center bearing journal. Measure width of main bearing cap at bearing bore.

Determine side clearance by subtracting bearing cap width from bearing journal width. Side clearance

should be 0.0059 to 0.0124 inch (0.150 to 0.314 mm) Maximum allowable clearance is 0.0157 inch (0.4

mm).

b.

If side clearance is not within these tolerance limits, recheck main bearing cap and crankshaft center

bearing journal. Replace in that order until side clearance is within tolerance limits

4-112

|