|

|||

|

|

|||

|

Page Title:

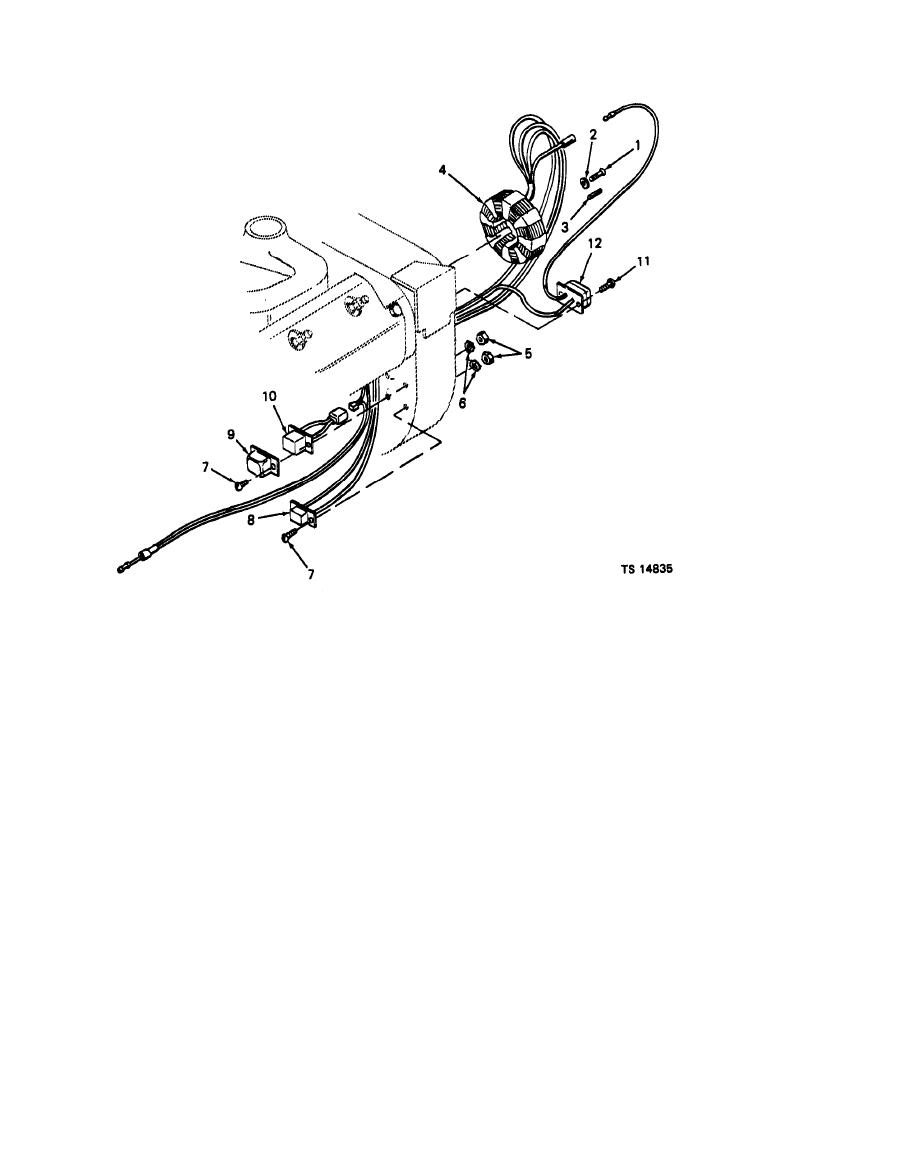

Figure 6-13. Flywheel alternator. |

|

||

| ||||||||||

|

|

TM 5-4320-273-14

1. Screw

7. Screw

2. Lockwasher

8. Rectifier module

3. Pin

9. Regulator module shield

4. Stator assembly

10. Regulator module

5. Nut

11. Screw

6. Lockwasher

12. Isolation diode

c. Cleaning and Inspection.

magnetism,

d. Installation.

WARNING

(1) Install isolation diode (12) using screws (11).

DRY CLEANING SOLVENT, P-D-680

(2) Be sure mounting surfaces of modules and

or P-S 661, wed to clean parte is

engine are clean. Hold regulator module (10),

potentially dangerous to personnel

regulator module shield (9), and rectifier module (8)

and property. Avoid repeated and

in place and secure with screws (7), lockwashers (6),

prolonged skin contact. DO NOT use

and nuts (5),

near open flame or excessive heat.

(8) Install stator assembly (4) to flywheel shroud

Flash point of solvent is 100 to 138F

and engine gear cover by installing pins (3), lock-

(38 to 60C).

washer (2), and screw (l).

(1) Clean metal parts with cleaning solvent (fed,

(4) Install the Woodruff key (5, fig, 6-4) in the

spec, P-D-680); dry thoroughly. Clean all nonmetallic

crankshaft keyway. Position the flywheel (4) on the

parts with a cloth dampened lightly with cleaning

crankshaft so that the keyway aligns with the

solvent, Take care to prevent saturating the stator

Woodruff key in the shaft keyway. Tap the flywheel

coils when you clean these parts.

onto the shaft with a soft hammer.

(2) Inspect leads for frayed wires or loose con-

(5) Secure the flywheel to the crankshaft with

nections; replace all damaged leads.

nut (2) and lockwasher (3).

(8) Inspect the stator assembly (4) for damaged

(6) Drive in hand crank pin (1) so that ends

insulation, gouges, or other damage. Replace a

protrude evenly.

damaged stator.

(7) Replace the flywheel screen (3, fig, 6-3) with

(4) Inspect inserts in flywheel for loSS of

screws (1) and lockwashers (2).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |