|

|||

|

|

|||

|

Page Title:

Detailed Lubrication Information. |

|

||

| ||||||||||

|

|

TM 5-4320-273-14

a. Keep lubricants in closed containers and store

in a clean, dry place away from external heat. Allow

no dust, dirt or other foreign material to mix with the

lubricants.

6. Store lubrication equipment in a place where it

will be safe from damage. Clean the equipment

before and after use.

c. Keep all external parts not requiring lubrication

free of lubricants. Wipe all lubrication points free of

dirt and grease before lubricating, and clean all

lubrication points after you lubricate them to

prevent accumulation of dirt.

operating under unusual conditions. You generally

have to change the oil more frequently than normal

under cold weather operation conditions because con-

tamination by fuel dilution and sludge formation will

increase under dusty and sandy conditions because

contamination by foreign matter increases.

Engine crankcase lubrication consists mainly of

changing the oil in the crankcase and servicing the

oil filter (LO 5-4320-273-12). Proceed as follows:

a. Run the engine long enough to heat it to

operating temperature. The warm oil will drain from

the internal engine parts much more rapidly than

cold oil and also will carry more dirt and sludge with

it as it drains.

6. Place a suitable container under the engine

drain port before you remove the oil pan drain plug

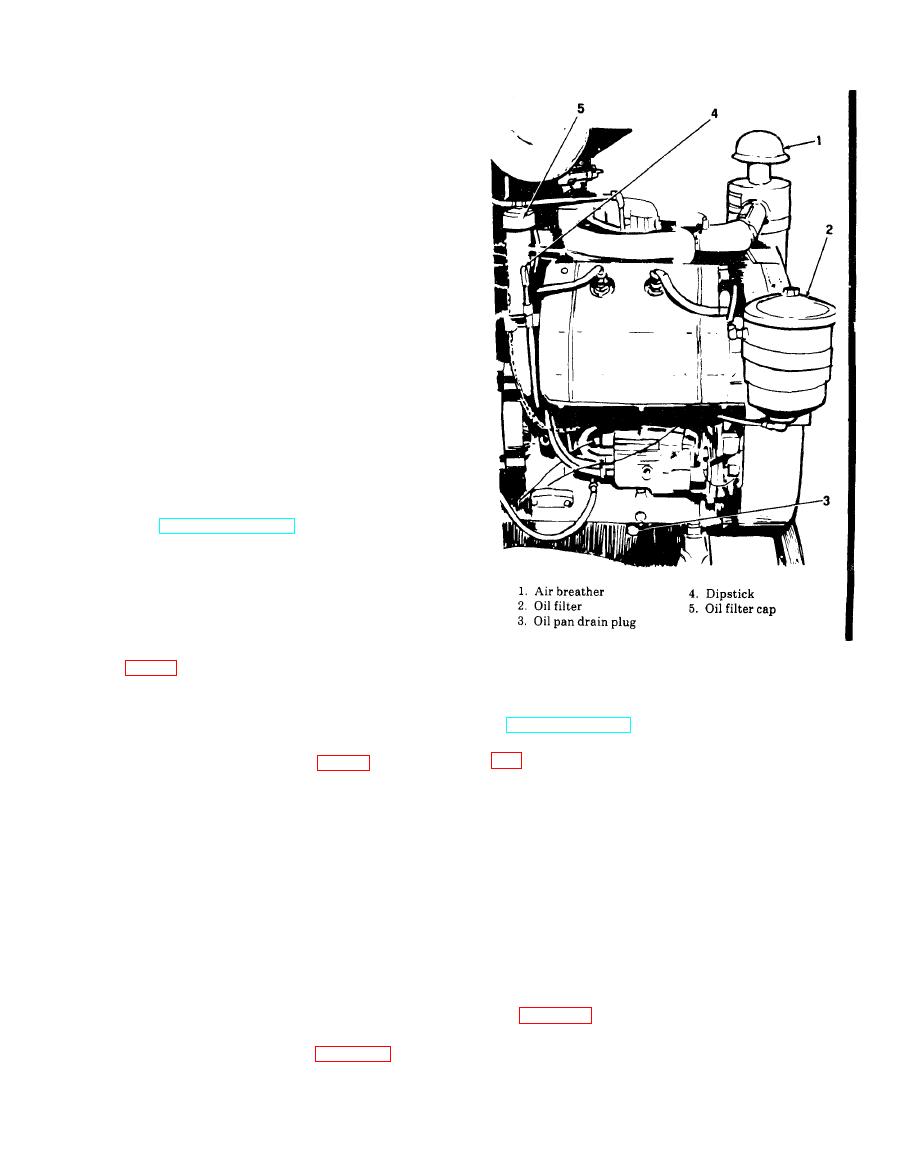

Figure 3-2 Engine lubrication.

(3, fig. 3-2). Allow the oil to drain fully.

must use the engine oil required for the particular

c. If engine is operated under extreme dusty or

temperature range which will be encountered, Refer

sandy conditions, you should replace the filter

to LO 5-4320-273-12.

element at every oil change.

f. Check the oil level on the oil level dipstick (4, fig.

d. Install the plug in the drain port.

level to be low, add enough oil through the oil filler

engine oil filler tube and pour 6 quarts (5.7 1) of

tube to bring the oil up to the proper level, Take care

engine oil into the engine, 5 quarts (4,7 1) for the

not to overfill.

crankcase and 1 quart (0.95 1) for the oil filter. You

Section Il. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

for correction and shall be made as soon as operation

3-4. General.

has ceased. If a deficiency is noted during operation

Preventive maintenance checks and services are

which would damage the equipment if operation

necessary to ensure that the pumping assembly is

were continued, stop operation immediately. You

ready for operation at all times. You must inspect the

shall record all deficiencies together with the correc-

assembly systematically so that any defects may be

tive action taken on DA Form 2404 (Equipment In-

discovered and corrected before they result in serious

spection and Maintenance Worksheet),

damage or failure.

should perform before, during, and after operation of

a. The preventive maintenance services to be per-

the pumping assembly and the approximate work

formed by you are listed in table 3-1 Defects

time required in tenths of man-hours.

discovered during operation of the unit shall be noted

Change 2 3-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |