|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

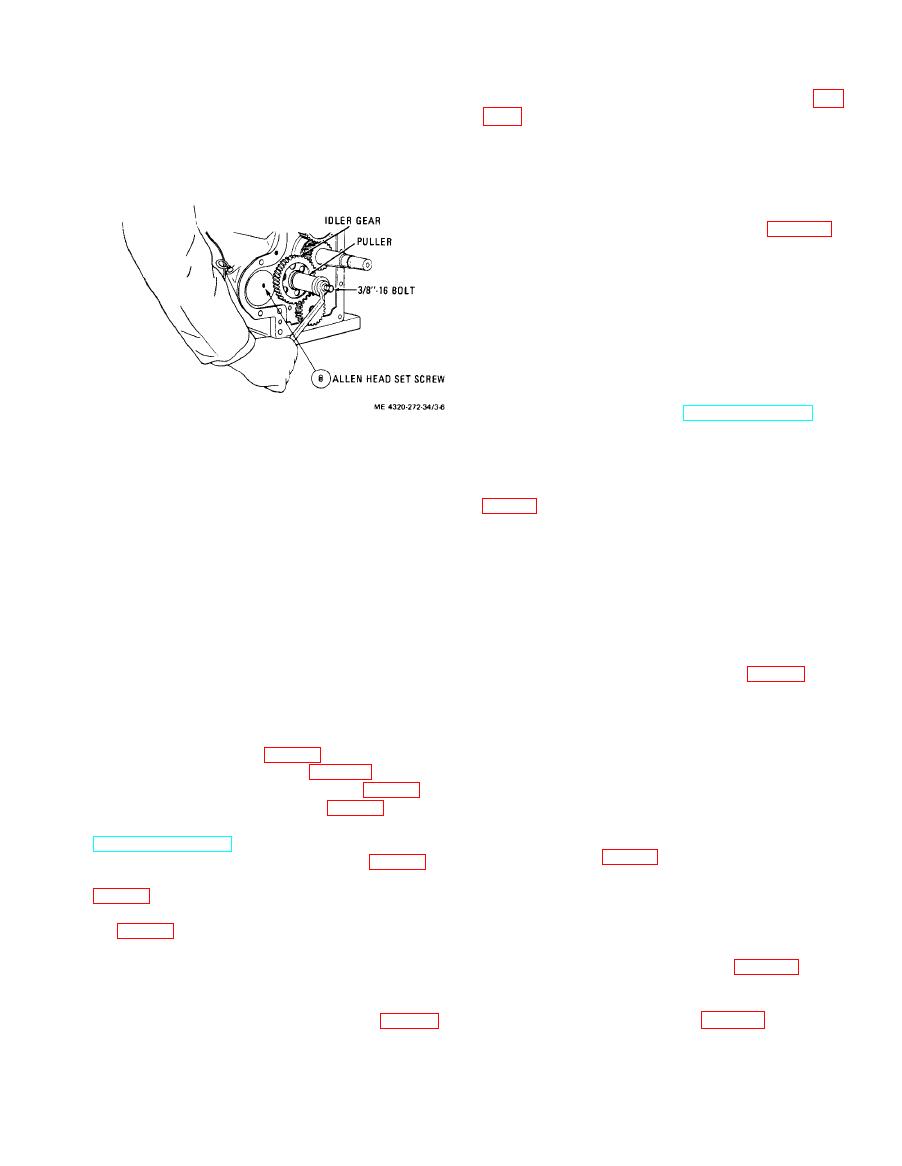

NOTE

b. Cleaning and Inspection.

The hole in the end of the idler shaft is

(1) Discard and replace oil pan gasket (25, fig.

tapped 3/8"-16.

(2) Clean oil pan (24) and drain plug (1) with

cleaning solvent (fed. spec. P-D-680; dry thoroughly.

(3) Inspect the oil pan for cracks, severe dents,

holes, damaged threads, and other damage; replace a

damaged oil pan.

when you install oil pan (24). Install in reverse order of

removal. Be sure to note the following

(1) Install the oil pan with the deep end toward

the oil pump.

(2) Tighten the oil pan mounting screws (22)

to 6 to 9 foot-pounds torque. Tighten the screws

evenly and alternately in increments to prevent undue

stress on the oil pan.

(3) Refill crankcase with oil before restoring

the engine to service. Refer to LO 5-4320-272-12.

a. Removal.

c. Cleaning and Inspection.

(1) Clean the idler gear and shaft with cleaning

(1) To remove oil filer and breather cap (29,

solvent (fed. spec. P-D-680) and dry thoroughly.

pull at the same time.

(2) Inspct the idler gear for cracks, distortion,

chipped, cracked, or broken teeth. Replace idler gear if

(2) To remove oil filler tube, rotate and pull

damaged.

from engine block. Remove oil strainer (31).

(3) Check the idler gear shaft for cracks, distor-

(3) Remove oil level gage rod (32); remove

tion, or excessive wear of shaft or shoulder. Replace

adapter tube (33) if it is damaged.

worn or damaged shaft.

b. Cleaning and Inspection.

c. Installation.

(1) Clean all parts with cleaning solvent (fed.

(1) In installing the idler gear shaft, you must

spec. P-D-680); dry thoroughly.

be sure the oil groove in the shaft is facing up. Place the

(2) Inspect the oil strainer (31, fig. 3-13) for

idler gear on shaft before you drive shaft into

distortion, damaged sealing surfaces, holes in the

crankcase. Use a pastic hammer. Take care to main-

screen, clogging, or other damage. Replace a damaged

tain a 0.003- to 0.004-inch clearance between idler

strainer.

gear hub and shoulder to shaft. Retain shaft by

(3) Inspect the oil level gage rod (32), making

installing the setscrew (19, fig. 3-13).

sure it is straight and in good condition.

(2) Install the gear cover (para 3-10).

(4) Check all parts for cracks, dents, distor-

(3) Install the governor assembly (para 3-9).

tions, or other damage; replace damaged parts.

(4) Install the air shrouding (para 3-7).

c. Installation. Install oil filler and level gage in

(5) Install the carburetor and manifolds

the reverse order of removal. Use Loctite to secure

(TM 5-4320-272-12).

adapter tube (33, fig. 3-13) in engine block. The filler

(6) Install the flywheel alternator (para 3-6.

tube (30) is a push fit in the block. If necessary, rotate

(7) Install the flywheel assembly to the engine

the tube back and forth to seat it fully.

(8) Install the oil filter to the flywheel shroud-

3-14. Engine Ol Pump

ing (para 3-4).

a. Removal and Disassembly.

(1) Remove the engine oil pan (para 3-12).

3-12. Oil Pan

a. Removal.

NOTE

(1) If you have not already drained oil for

The engine support (7, fig. 3-13) is

engine overhaul, remove the drain plug (1, fig. 3-13)

mounted over the pipe plug and setcrew

and drain the engine oil into a suitable container.

which must be removed for oil pump

(2) Remove the 14 screws (22) and lock wash-

removal. You must remove the support

first, if you have not done so already.

remove the oil pan and gasket (25).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |