|

|||

|

|

|||

|

Page Title:

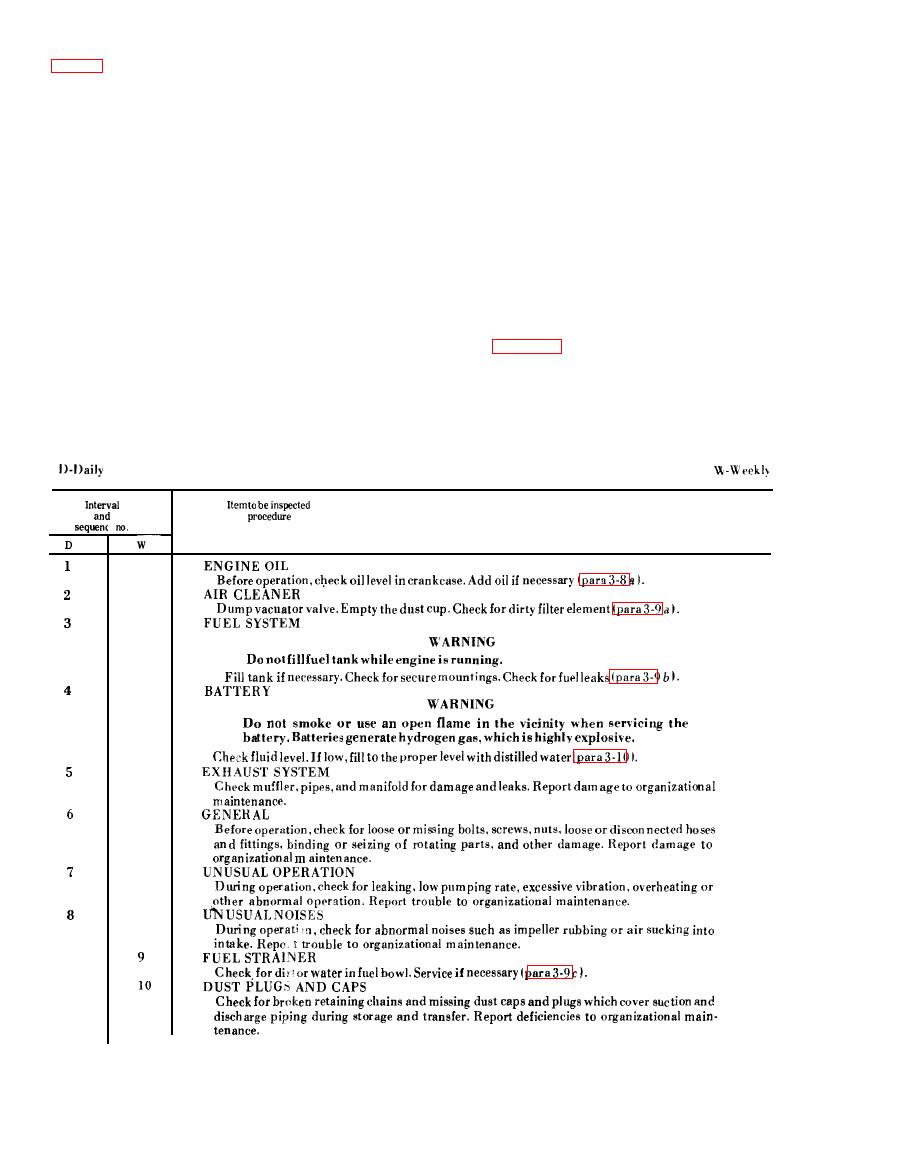

Section II. PREVENTIVE MAINTENANCE CHECKS AND SERVICES |

|

||

| ||||||||||

|

|

the oil filler pipe to bring the oil up to the proper

level. Take care not to overfill.

find the oil level to be low, add enough oil through

Section II. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

is noted during operation which would damage the

3-4. General

equipment if operation were continued. You shall

To insure that the pumping assembly is ready for

record all deficiencies and shortcomings together

operation a t a l l t i m e s , you must inspect it

with the corrective action taken on DA Form 2404

systematically so that defects may be discovered

(Equipment Inspection and M a i n t e n a n c e

and corrected before they result in serious damage

Worksheet). Correct all deficiencies at the earliest

or failure. The necessary preventive maintenance

possible opportunity.

services to be performed by you are listed in table 3-

1. The sequence numbers indicate the order in

3-5. Preventive Maintenance Checks and

which you should perform the preventive main-

Services

tenance checks and services. Defects discovered

Refer to table 3-1 for a listing of operator / crew

during operation of the unit shall be noted for

preventive maintenance checks and services.

correction, to be made as soon as operation has

ceased. Stop operation immediately if a deficiency

Checks and Services

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |