|

|||

|

|

|||

|

Page Title:

Section IV. OPERATION UNDER USUAL CONDITIONS |

|

||

| ||||||||||

|

|

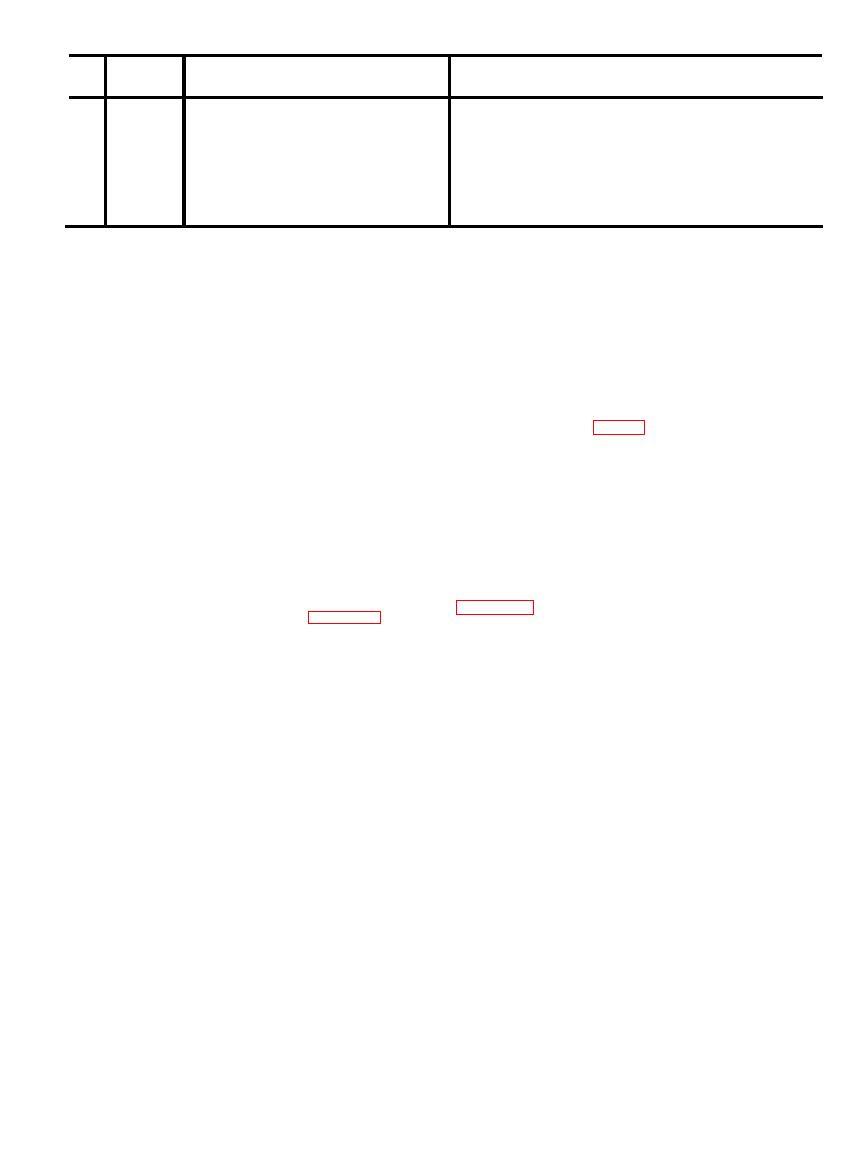

Table 2-1. Controls

Figure

Index

Name

Operation

and

use

no.

no.

Fuel shutoff cock

Shuts off fuel to the carburetor.

2

2-2

Choke control

When closed (top of lever moved away from engine), it

1

2-2

provides an extra rich fuel-air mixture to aid starting. When

fully open, it provides a normal fuel mixture.

Engine stop button

When pressed, it grounds the magneto primary to prevent a

3

2-2

spark at the spark plug, stopping the engine.

Nozzle operatiug handle

2-3

When handle is squeezed, it allows fuel to flow from nozzle.

1

When released, it stops flow of fuel.

Section IV. OPERATION UNDER USUAL CONDITIONS

2-7. General

Caution. Do not run the pump when it is

dry. Running a dry pump will damage the seal,

a. The instructions in this section are for the

causing seal leaks.

information and guidance of personnel responsible

b. Prime the pump before initial starting or

for operation of the pumping assembly.

before starting the pump any time after the pump

b. The operator must know how to perform

body has been drained. To prime the pump, remove

every operation of which the pumping assembly is

the priming cap (2, fig. 2-1) from the top arm of the

c a p a b l e . This section contains instructions on

discharge cross and fill the pump body with the

starting and stopping the pumping assembly, on

fluid which is to be pumped. Install the cap on the

operation o f t h e p u m p i n g a s s e m b l y , a n d o n

top arm of the discharge cross.

c o o r d i n a t i n g the basic motions to perform the

Warning: Do not remove the caps from the

specific tasks for which the equipment is designed.

discharge cross to check for priming or for any

Since nearly every job presents a different problem,

o t h e r reason while the engine is running.

the operator may have to vary given procedures to

Flammable liquid may be discharged, resulting

fit the individual job.

in fire.

2-8. Starting

c. Start the pumping assembly as shown in

a. P e r f o r m a l l b e f o r e - o p e r a t i o n p r e v e n t i v e

maintenance checks and services (table 3-1).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |