|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(2) Inspect for broken or damaged wire insulation;

engine in the RUN position and to interrupt spark in

the STOP position. The OIL switch, when released,

worn, burned, or loose terminals, and cracked,

completes a connection to the oil pressure gage to

broken, or damaged parts.

provide an indication of engine oil pressure. The

(3) Check switches for proper continuity. Refer to

START switch, when depressed, completes a con-

nection to the engine starter to turn over the engine.

b . Tachometer and Sender. Engine speed is con-

(4) Check the tachometer and oil pressure gage for

stantly monitored by the electrical sending unit,

cracked dial glasses, discolored or illegible

dials, or other damage.

which is mounted on the engine governor, and which

sends electrical impulses to the tachometer mounted

(5) Repair or replace damaged parts.

on the control panel. The tachometer provides an

i n d i c a t i o n of engine speed in rpm's.

c. Reassembly and Installation.

c . Battery. T h e battery supplies the electrical

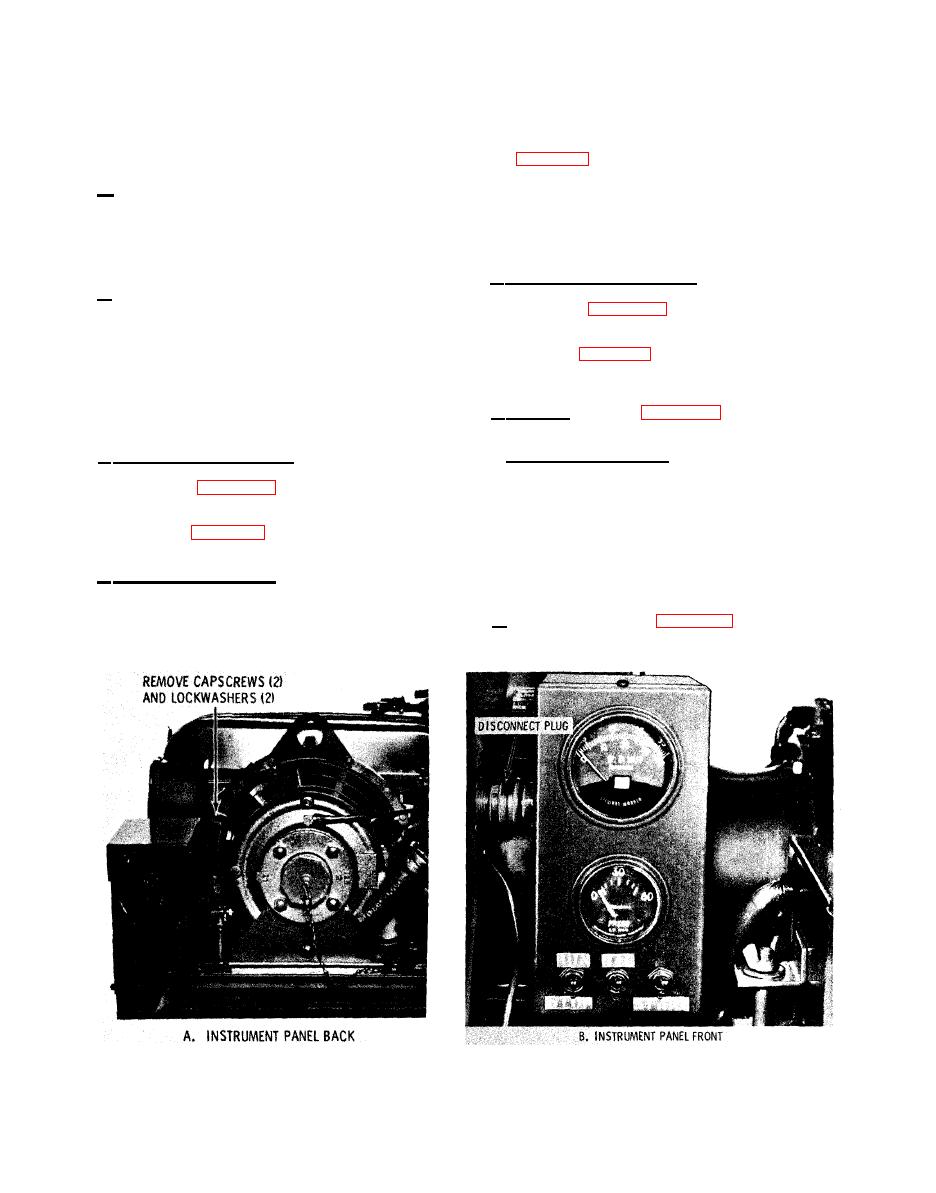

(1) Refer to figures 3-5 and 1-3 and reassemble

power necessary to operate the starter to start the

the control panel.

engine. It is a 24-volt, lead-acid type, and it is

mounted in a covered battery box which is secured

(2) Refer to figure 3-4 and install the control panel.

to the skid base. The negative battery terminal is

connected to the frame with a ground strap. The

3-13. ELECTRICAL SENDING UNIT

positive battery terminal connects to a terminal on

the starter by means of a battery cable.

a. Removal. Refer to figure 3-6 and remove the

electrical sending unit.

3-12. CONTROL PANEL

b. Cleaning and Inspection.

a. Removal and Disassembly.

--

(1) Refer to figure 3-4 and remove the control

(1) Clean sending unit with a cloth dampened lightly

with an approved cleaning solvent; dry thoroughly.

panel.

(2) Inspect sending unit for cracks, breaks, defec -

(2) Refer to figure 3-5 and disassemble the control

tive insulation, and other damage. Manually turn

panel as necessary to replace defective parts.

the shaft of the sender. It should rotate easily

without catching or binding. Replace a damaged

b. Cleaning and Inspection.

sender.

(1) Clean all electrical parts with a cloth lightly

c . Installation. Refer to figure 3-6 and install the

dampened with an approved cleaning solvent;

electrical sending unit.

dry thoroughly.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |