|

|||

|

|

|||

|

Page Title:

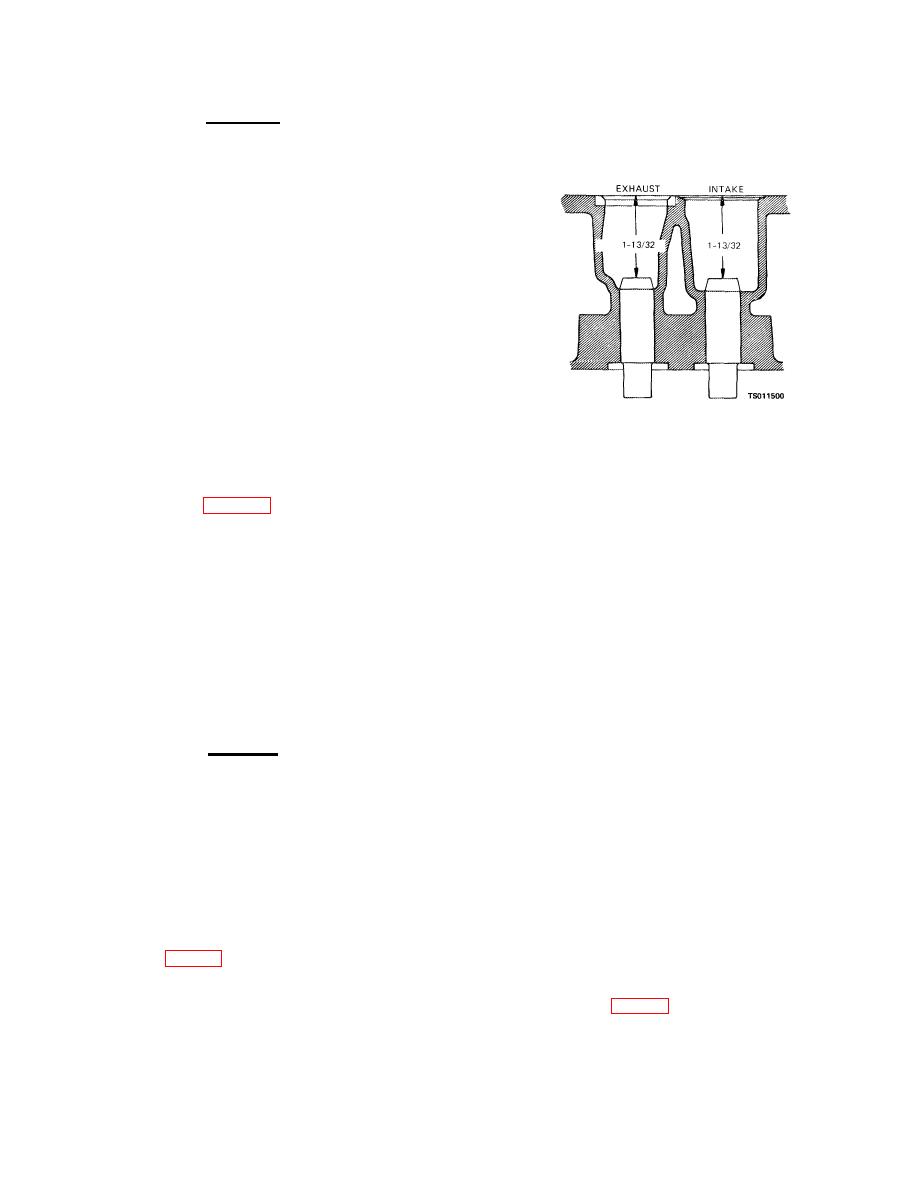

Figure 4-4. Valve guide installation dimensions. |

|

||

| ||||||||||

|

|

TM 5-4320-234-34

c. Cleaning, Inspection, and Repair.

the original valve seats to a diameter of 1.3535 to

1.3545 inches (3.3837 to 3.3862 cm). This will provide

WARNING

the required press fit.

If valve seats had been

Clean all parts in a well-ventilated

counterbored previously, rebore to 0.01 inch (0.0250

area. Avoid inhalation of solvent

cm)

fumes and prolonged exposure of

skin to cleaning solvent. Wash

exposed skin thoroughly.

Dry

cleaning solvent (Fed. Spec. P-D-

680) used to clean parts is

potentially

dangerous

to

personnel and property. Do not

use near open flame or excessive

heat. Flash point of solvent is 100

F. to 138 F. (38 C. to 59 C. ).

(1) Clean the valves, valve springs, and

valve tappet assemblies with cleaning solvent (Fed.

Spec.

P-D680); dry thoroughly.

Remove carbon

deposits with a wire brush.

(2) Clean the valve guides installed in the

Figure 4-4. Valve guide installation dimensions.

block with a valve guide cleaner or wire brush. Remove

oversize to provide a 0.003 to 0.005 inch (0.0075 to 0.

all lacquer and other deposits.

0125 cm) press fit. Counterbore deeply enough so that

(3) Clean the valve seats with a wire brush.

the boring tool will clean up the bottom of the bore to

(4) Inspect the valves for cracks, bent stems,

ensure proper heat conduction from the valve insert.

distortion, and wear (table 4-1). If the valves are not

Chill the valve seats in dry ice for 20 minutes. Install

seriously damaged, regrind them. After grinding, the

the valve seat in place with a piloted driver, by using an

valve head thickness must be at least 50 percent of a

arbor press or by applying light blows with a hammer

new valve's thickness. You must replace the valves if

until the valve seat is resting against the bottom of the

they are ground to less than this amount. Check the

bore. Roll or peen the valve seat into place.

reground valves on V-blocks with an indicator. The

(8) Check the valve springs for cracks and

contact face must be true with the stem to within 0.002

distortion. Test compression strength with a spring

inch (0.0050 cm).

tester. Compression strength must be as follows:

(5) Check for loose or worn valve guides.

Length

Load (minimum)

Check the internal diameter of the valve guide with a

1-45/64 inches (closed) (4.2577 cm)

42 pounds (18.90 kg)

telescope gage and a micrometer. Replace guides that

1-27/64 inches (open) (3.5547 cm)

86 pounds (38.70 kg)

are worn to a bell-mouthed shape or guides that have a

(9) Grind the valve seats. The seat angle of

maximum diameter of more than 0.3447 inch (0.8617

the intake valve is 30 The seat angle of the exhaust

.

cm).

valves is 45 Use a dial indicator to check the valve

.

CAUTION

seat for runout. The total indicator reading must not

Do not attempt to ream the valve

exceed 0.002 inch (0.0050 cm). Clean the valve seat

guides after seating them. Guides

and surrounding area thoroughly after grinding.

are pre-reamed and coated.

(10) After you have refaced and reground the

Further reaming will remove the

valves and seats, coat each seat lightly with Prussian

coating.

blue and drop the valve into place, oscillating it slightly

(6) If the valve guides are worn or damaged,

to transfer the blue pattern to the valve face. This

press out the guides from the combustion side, using a

should show a contact width of 1/16 to 3/32 inch (0.

driver that is slightly smaller than the external diameter

1562 to 0.2342 cm), and should fall well within the width

of the guide. With the driver, press in new guides from

of the valve face, leaving at least 1/64 inch on either

the combustion side. When properly seated, valve

side of the contact area. If the contact area is greater

guide tops will be 1-13/32 inches (3.5155 cm) from the

than 3/32 inch (0.2342 cm), narrow the contact area by

top of the block (fig. 4-4).

grinding the outside diameter of the seat with a 15

(7) Check the exhaust valve seat inserts for

stone or by grinding the inside diameter of the seat with

cracks or loose mountings. Pull out faulty valve seat

a 60or 75stone (fig. 4-5). After the

inserts. Replace original valve seats with new 0.010

inch (0.0250 cm) oversized valve seats. Counterbore

4-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |