|

|||

|

|

|||

|

Page Title:

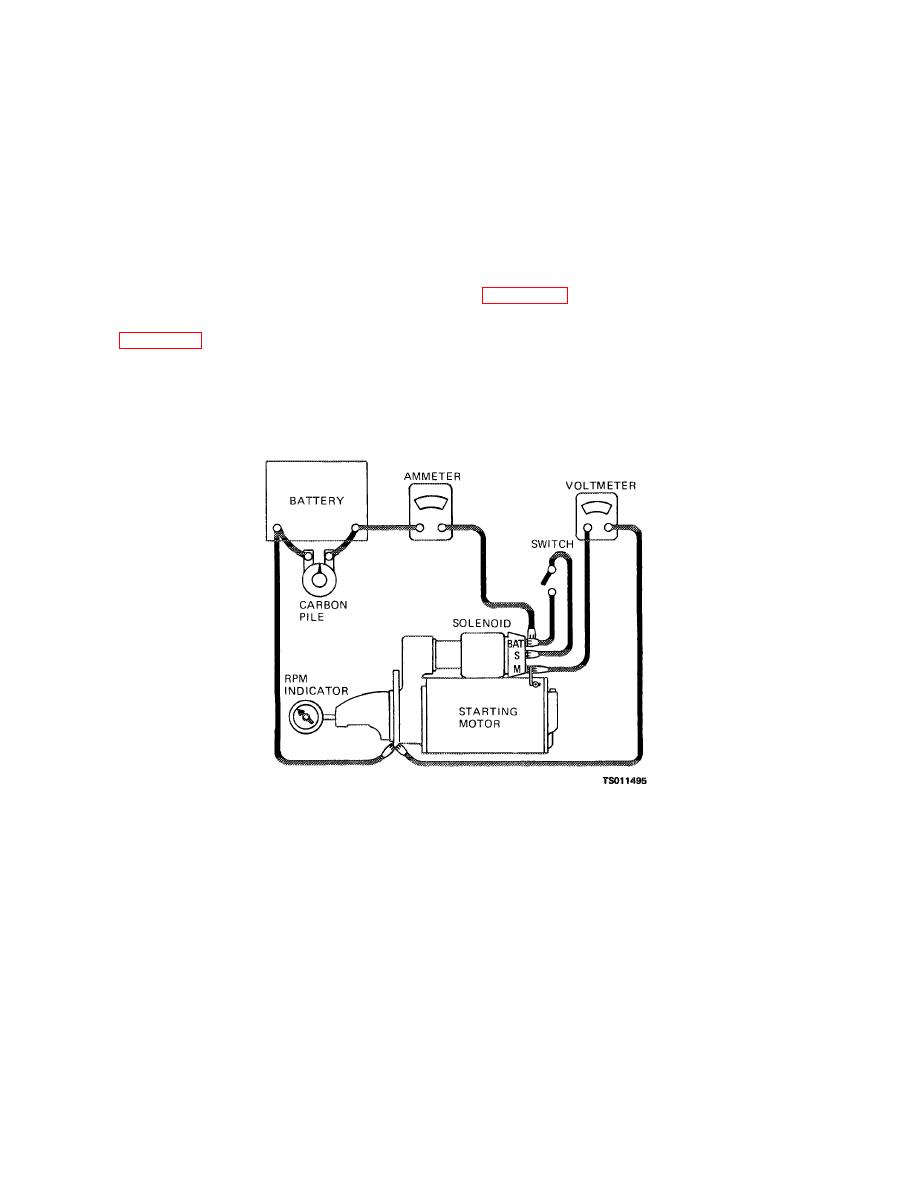

Figure 3-16. Starting motor no-load test setup. |

|

||

| ||||||||||

|

|

TM 5-4320-234-34

(2) Remove the support pins (6) to release

NOTE

the grounded brush holders (10), insulated brush holders

Thecommutator on the armature shaft must be smooth and concentric,

(11), and brush springs (7) from the brush supports.

free from burrs, scoring, high segments, burned segments, or other

Remove the brush screws (8) that secure the brushes

damage. You should replace the starting motor if the commutator is

(9) to the brush holders; you can now remove the

damaged.

brushes.

(6) Install the commutator end frame (4) with

(3) Remove the screws (14), nuts (12), and

the through bolts (3).

washers (13) that secure the brush leads (15) to the

d. Testing. To perform a no-load test,

brush support; remove the brush leads.

connect the starting motor in series with a fully charged

(4) Replace the brushes if you find them

24-volt battery, an ammeter of 0to 500-ampere range

chipped, oil soaked, or worn to less than 5/16 inch

and a large variable carbon pile resistor as shown in

(0.7812 cm). Replace any other parts that are cracked,

worn, or distorted.

You will also need a tachometer to measure armature

(5) Install the brushes and related parts as

speed. Energize the starting motor and adjust the

shown in figure 3-15. Before installing the commutator

variable resistor until you have a reading of 20 volts.

end frame (4), seat the brushes on the commutator

Armature rotation should be within the range of 3300 to

using 00 sandpaper.

5600 rpm with a current draw between 40 and 75

amperes. Interpret the results as follows:

Figure 3-16. Starting motor no-load test setup.

(1) Current draw and no-load armature speed

commutator bars), or lack of continuity between brushes

within the above limits indicate normal condition of the

and commutator.

starting motor.

(5) Low free speed with low current draw

(2) Low free speed or high current draw

indicates high internal resistance due to poor

indicates too much friction, caused by damaged

connections, defective leads, or a dirty commutator.

bearings or a bent shaft, a shorted armature, or a

(6) High free speed with high current draw

grounded armature or field.

indicates a shorted field.

(3) No rotation with high current draw

e.

Disassembly. Disassemble the start

indicates a grounded field terminal or frozen bearings.

motor

(4) Failure to operate with no current draw in

dicates an open field circuit, open armature coils (this

condition is normally accompanied by badly burned

3-18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |