|

| |

TM 10-4320-342-24

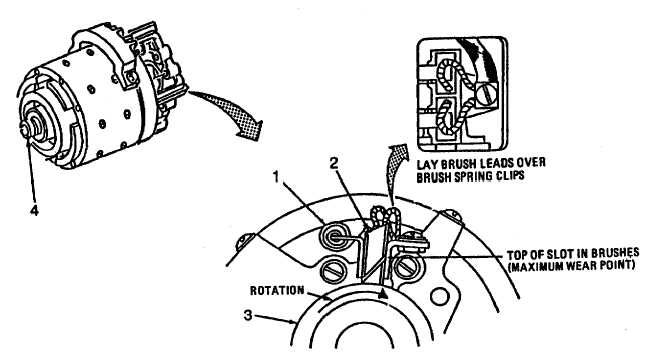

3-22. STARTER-GENERATOR REPAIR - continued.

Refer to Figure 3-37.

(37)

Seat new brushes as follows:

(a)

Raise each brush spring clip (1) and lift brush (2) away from the commutator (3) until the brush spring can

hold the brush in position by resting against the side of the brush.

(b)

Place a strip of 5/0 or finer sandpaper, slightly wider than the width of the brush, around the commutator (3)

with the sand side out. Cut the sandpaper strip to one inch greater than the commutator circumference.

Secure one end of the sandpaper strip to the commutator surface with masking tape so that the taped end

will lead in the direction of rotation, and the other end will remain loose and overlap taped end.

(c)

Lower brush (2) in place against the sandpaper, and carefully rotate the armature shaft (4) by hand in the

normal direction of rotation until a full seat is obtained on each brush. Do not sand excessively.

WARNING

Compressed air can blow dust into the eyes. Wear eye protection. Do not exceed

30 psig air pressure.

(d)

Remove the sandpaper, remove all carbon dust with dry, compressed air.

Figure 3-37. Seating New Brushes

3-86

|