|

| |

TM 9-2350-285-20

1-14. EQUIPMENT OPERATION (continued).

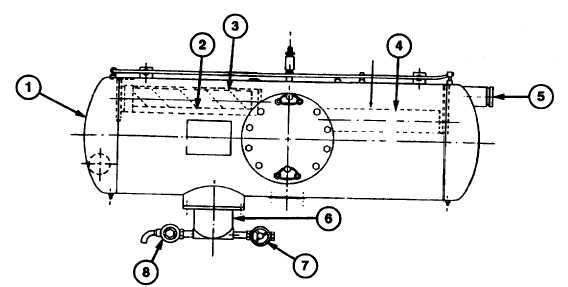

FILTER/SEPARATOR ASSEMBLY

FILTER/SEPARATOR: Provides filtering capabilities to remove contamination and condensation of fuel. The filter/

separator consists of an aluminum tank (1) containing 15 filter elements (4) and five second-stage water separator

assemblies (3) containing 15 monitor fuses (2). Fuel under pressure from the pump enters the filter tank inlet (5) and

flows through the 15 filter elements (4), where solid particles are removed. The fuel then flows through the five second

stage water separator assemblies (3), which further filter out smaller solid particles and coalesce water particles to be

collected in the filter sump (6). Coalescence is a process by which many small droplets of free water in the fuel are

collected to form larger water drops. These large water drops are then released into the filter sump (6).

AUTOMATIC DRAIN VALVE: As water accumulates in the filter sump (6), a float rises. When the float reaches a certain

level, a valve will open in the automatic drain valve (8). This allows pump pressure to be applied to a diaphragm valve,

opening the automatic drain valve (8). Water is then ejected out of the filter sump (6) through the automatic drain valve

(8). As water Is being ejected, fuel flow is continued.

MANUAL DRAIN VALVE: Used primarily during cold-weather operations. Water accumulated in the filter sump (6) may

freeze. ft is important that the manual drain valve (7) on the filter sump (6) be opened after each operation, to drain the

water accumulation. Be sure to close the manual drain valve (7) after draining.

MONITOR FUSES: Each of the five-second-stage water separator assemblies (3) is equipped with three monitor fuses

(2). The fuses are fuel contaminant monitoring devices located downstream" of the second stage. The fuses restrict the

fuel flow when water and solid contaminants are present in the fuel stream.

1-12

|