|

| |

TM 9-2330-398-24

2-63.

HUB AND BRAKEDRUM ASSEMBLY REPLACEMENT (continued).

4.

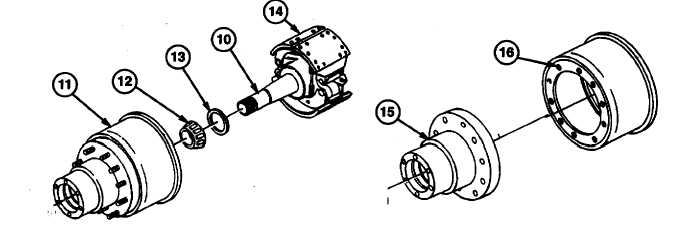

Slide hub and brakedrum assembly (11) off spindle (10). If hub and drum assembly (11) binds on brakeshoes

(14) when partially installed, loosen manual adjustment hex on slack adjuster (para 2-50d).

5.

Remove inner wheel bearing (12) from hub and brakedrum assembly (11) or spindle (10).

6.

Using seal puller, remove seal (13) from spindle (10). Discard seal, if required.

7.

Remove 10 wheel studs, nuts, and lockwashers (para 2-74). Separate hub (15) from brakedrum (16).

b.

CLEANING AND INSPECTION

WARNING

• Dry-cleaning solvent P-D-680 is toxic and flammable. Always wear protective goggles and

gloves, and use only in a well-ventilated area. Avoid contact with skin, eyes, and clothes, and

DO NOT breathe vapors. DO NOT use near open flame or excessive heat.

• Compressed air used for drying or cleaning purposes must not exceed 30 psi (207 kPa). Wear

protective clothing (goggles and gloves, etc.) and use caution, to avoid injury to personnel.

CAUTION

• DO NOT clean parts with gasoline, in a hot solution tank, or with water and alkaline solutions.

• DO NOT use compressed air to spin bearings.

1.

Thoroughly clean all parts with dry-cleaning solvent and stiff fiber brush. Make sure parts are completely dry. Use

low-pressure compressed air to dry parts.

2.

Inspect hubcap (3) for damage to flange that would allow water to leak into wheel bearings. Replace if damaged.

3.

Check for damage to threads of studs, screws, and nuts. Replace if damaged.

4.

Inspect brakedrum (16) for pitting or scoring. If brakedrum (16) is damaged, notify Direct Support maintenance.

5.

Inspect hub (15) for rust, pitting, or cracks. Replace if damaged.

2-153

|