|

| |

TM 9-2330-272-14

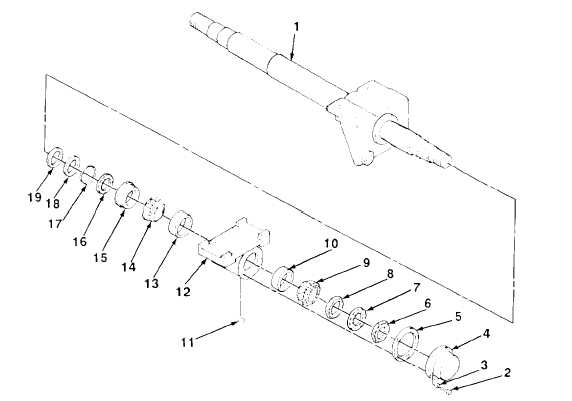

4-53. SPRING SEAT REPLACEMENT (Con’t).

3.

Tap spring seat (12) with a soft hammer to loosen outer bearing cone (9). Remove outer bearing cone from

spring seat and cross tube (1).

4.

Remove spring seat (12) from cross tube (1). Seal (15) will remain in spring seat.

5.

Remove seal (15), inner bearing cone (14), and pipe plug (11) from spring seat (12). Discard seal.

b. CLEANING AND INSPECTION

WARNING

Dry cleaning solvent, P-D-680, is toxic and flammable. Always wear protective goggles

and gloves, and use only in a well-ventilated area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO NOT use near open flame or excessive heat.

The solvent’s flash point is 100°F-138°F (38°C-59°C). If you become dizzy while

using cleaning solvent, immediately get fresh air and medical help. If solvent contacts

eyes, immediately wash your eyes and get medical aid.

1.

Clean spring seat and cross tube with dry cleaning solvent and inspect for cracks or other damage. Replace

spring seat if damaged. Notify Direct Support Maintenance if cross tube iS damaged.

NOTE

If outer and inner bearing cones need replacing, bearing cups must also be replaced.

2.

Clean and inspect outer and inner bearing cones in accordance with TM 9-214. Discard if damaged.

TA702760

4-108

|