|

| |

TM 55-2915-335-30&P

2-16. MOTOR COVER - lNSPECT/REPLACE (Cont)

2-16

c.

d.

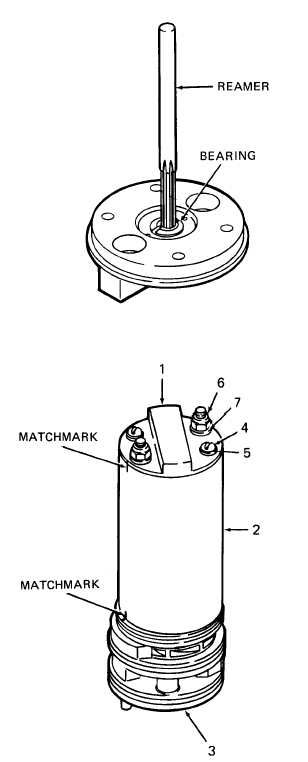

Check Bearing I.D. Using plug gage (Item 2, Ap-

pendix B, Section III) check bearing bore. If

0.3135 GO gage does not pass through bearing,

ream bearing as follows:

(1)

(2)

Install reamer (Item 1, Appendix B, Section

III) in drill press. Set drill press spindle speed

to between 560 and 690 RPM.

Lay motor cover flat on support plate of drill

press. With drill OFF, bring reamer down to

bearing. Center bearing bore to reamer.

NOTE

Make only one quick pass in and out of

bearing bore. If reamer is allowed to dwell

in bore, too much bearing material will be

removed.

(3)

(4)

Hold cover in place on support plate. Turn

drill press ON. Bring reamer down slowly to

top of bearing. Ream bearing to size with one

quick pass in and out of bearing bore.

Using plug gage (Item 2, Appendix B, Section

III) check bearing bore diameter D. If 0.3145

NO GO gage passes through bearing, replace

bearing.

TI INSPECT bearing and motor cover. Make sure

bearing diameter D is within dimensions specified,

and visually check to make sure bearing is fully

seated and not chipped or damaged.

5. COVER INSTALLATION

a.

b.

c.

2-48

Position pump cartridge up, as shown.

If reinstalling old cover on field tube, make sure

that matchmarks between field tube (2) and

cartridge housing (3) are in-line.

Hold cover (1) above field tube (2) with

matchmarks in-line. Turn brush holder to line up

screw holes in brush card with holes in cover.

GO TO NEXT PAGE

|