|

| |

TM 55-2915-335-30&P

Table 2-2. Maintenance Troubleshooting - Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

8. PUMP ASSEMBLY LEAKS FUEL

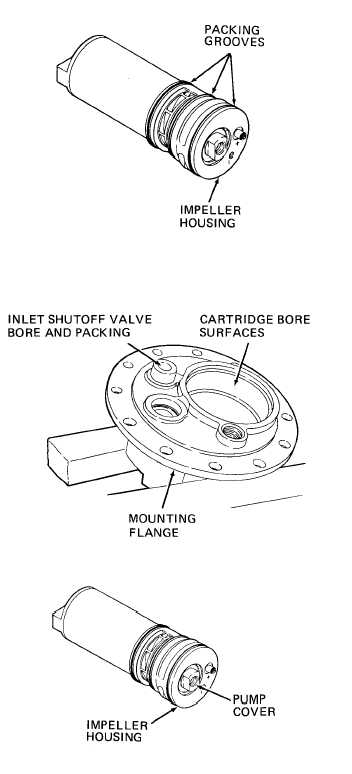

Step 1. Check packing grooves on cartridge.

Remove pump cartridge from housing

(paragraph 2-10). Remove preformed packings

from packing grooves. Run your finger along

the packing groove in the impeller housing.

Feel for any scratches or sharp edges that may

damage preformed packing. If no defects are

found, go to Step 2.

Replace or repair damaged im-

peller housing per instructions

and illustrations in paragraph

2-24.

Step 2. Check cartridge bore surfaces in pump

housing. Using a flashlight, visually inspect

cartridge bore surfaces in pump housing for

nicks, burrs, or scratches. Inspect exposed sur-

faces of housing for cracks. Visually check the

mounting flange for nicks, burrs, or scratches.

If no defects are found in pump housing/

mounting flange, go to Step 3.

If damaged, inspect and repair

pump housing/mounting flange

per instructions and illustra-

tions in paragraph 2-15.

Step 3.

Check packing seal between inlet

shutoff valve stem and pump housing. Remove

and inspect shutoff valve (paragraph 2-14).

Visually check valve stem and packing groove

in pump housing for burrs or scratches. If not

defective, go to Step 4.

If damaged, replace or repair

pump housing or valve stem per

instructions and illustrations in

paragraph 2-14.

Step 4. Check for faulty seal between pump

cover and impeller housing. Remove, clean,

and inspect pump cover per paragraph 2-21.

Check condition of packing groove.

If defective, repair or replace

per instructions and illustra-

tions in paragraph 2-21.

2-19

|