|

| |

TM 5-5430-210-12

2-11.

Berm Construction, 50,000-Gallon

(189,250-Liter) Tank. The following instructions

are for a 26-foot by 66-foot (7.924-meter x

20.117-meter) (flat dimensions).

NOTE

A minimum of three-foot (one-meter)

working clearance is necessary between

the side of the tank and the berm on all

four sides.

a. Clear and level an area 30 feet by 70 feet

(9.14 meters x 21.34 meters).

b. Inspect area closely. Remove all sharp objects

from the leveled area.

c. Slope all four sides of the leveled area in to-

ward the center (fig. 2-15). The center should be no

more than nine inches (22.86 centimeters) below

ground level. If possible, provide a sand bottom ap-

proximately four inches (10.16 centimeters) thick.

d. Erect a four-foot (1.22-meter) high

berm around the outside of the sloped area.

earth

e. To provide a berm drain, place a 2-inch

(5.08-centimeter) pipe with a gate valve through

the bottom of the discharge end of the berm in

order to provide a means of draining accumulated

water. Valve should be normally closed; open valve

only to drain water from the bermed area.

M a k e c e r t a i n t h a t t h e v a l v e i s

c l o s e d a n d l o c k e d a f t e r

i n s t a l l a t i o n . I n v e n t o f t a n k

rupture, an open valve would permit

fuel to drain from berm and could

cause fire or explosion.

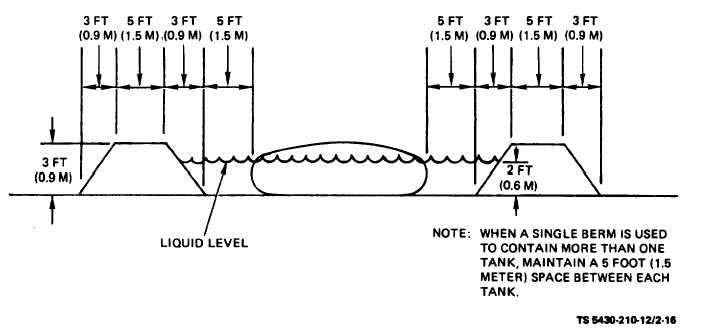

2-12. Typical Berm Cross Section. Figure 2-16

shows a cross section view with dimensions of a

typical berm.

Figure 2-16. Typical Berm Cross Section.

Section II. MOVEMENT TO A NEW WORKSITE

2-13. General. Whenever possible, prior to move-

purged of all residual fuel and fumes and cleaned

ment, unit assemblies should be disassembled,

and preserved for future use.

2-16

Change 5

|