|

| |

TM 5-4320-308-13

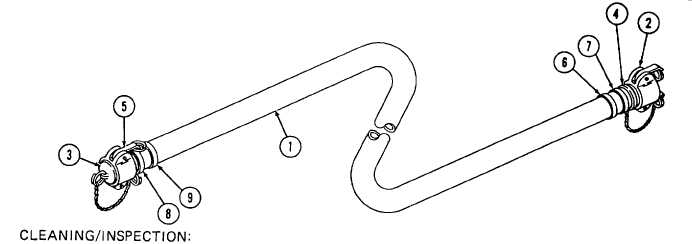

3-13. REPLACE DISCHARGE HOSE ASSEMBLY

This task covers:

Cleaning/Inspection

INITIAL SETUP

Equipment

General Safety Instructions

Condition

Para

Condition Description

Well-ventilated area required.

2-1

Discharge hose assembly re-

moved from pump.

WARNING

Death or serious injury could occur if fuel is not handled carefully. Use in a well-ventilated area

away from open flame, arcing equipment, ignition sources, heaters, or excessive heat. Always

store fuel in proper, marked containers. DO NOT SMOKE.

Death or serious injury could occur if compressed air is directed against the skin. Do not use

compressed air for cleaning or drying unless the pressure is/has been reduced to 30 psi (2. 06

bar) or less. When working with compressed air always use chip guards, eye protection, and other

personal protective equipment.

1

Flush hose (1) with clean diesel fuel. Wipe exterior of hose with a cloth dampened with diesel fuel.

2

Clean dust caps (2 and 3), adapter (4), coupler (5), and clamps (6, 7, 8, and 9) with clean diesel fuel and dry with

compressed air.

3

Inspect hose (1) for cracks, leaks, signs of deterioration, collapsed walls, and obvious damage. If hose is

damaged, replace discharge hose assembly.

4

Inspect adapter (4), clamps (6, 7, 8, and 9), and coupler (5) for obvious wear or damage. If adapter (4), clamps

(6, 7, 8, or 9), or coupler (5) are damaged, replace discharge hose assembly.

3-34

|