|

| |

TM 5-4320-308-13

4-18.

INSPECT/REPLACE CYLINDER (Continued)

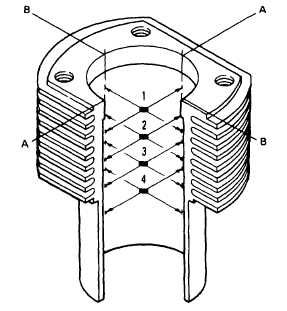

4 Measure cylinder bore at levels 1 to 4 of engine centerline axis A and crossline axis B. A normal or new bore

diameter should be 2.8740 to 2.8774 inches (73.00 to 73.09 mm). If wear limits for a normal bore cylinder have

been reached or exceeded, replace cylinder and piston. If measurements on axis A and axis B are different,

cylinder is out-of-round or has high spots. Replace cylinder and piston

5

Check that the top and bottom joint faces are smooth and flat. If damaged, replace cylinder and piston

REPAIR:

1

Remove slight ridges, score marks, and glaze with a hone equipped with 20-grit stones. Work hone up and down

rapidly the full length of the cylinder bore several times in a criss-cross pattern. Criss-cross pattern produces

hone marks on a 45-degree axis, which aids piston movement and helps prevent formation of ridges

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard's Solvent) is potentially

dangerous. Avoid repeated and prolonged breathing of vapors and skin contact

with the liquid. Do not use near open flame, arcing equipment, or other ignition

sources. Always wear eye protection and protective clothing. The flash point of

P-D-680 is 100° to 138°F (38° to 59°C)

Death or serious injury could occur if compressed air is directed against the skin.

Do not use compressed air for cleaning or drying unless the pressure is/has been

reduced to 30 psi (2.06 bar) or less. When working with compressed air, always

use chip guards, eye protection, and other personal protective equipment

2

Clean cylinder with dry cleaning solvent and dry with compressed air. Remove any burrs.

3

Recheck cylinder bore and out-of-round on repaired cylinder as described above. Replace if out of tolerance.

4-51

|