|

| |

TM 5-4320-308-13

4-15. TEST/REPLACE/ADJUST INJECTION PUMP (Continued)

NOTE

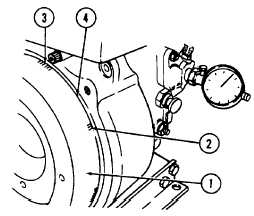

The position achieved above is the end of delivery. If the shim pack is of the correct

thickness, the timing marks on flywheel (1) (11.5 to 12.5 degrees) should align with reference

mark (4).

3

Block fuel hose (from fuel tank) using fuel

shutoff clamp 668 383 00.

4

If timing marks do not align with reference

mark (4), rotate outer face of dial gage

612 087 00 until "0" mark aligns

with

needle.

5

Slowly rotate flywheel (1) in either

direction to align timing marks of 11.5 to

12.5 degrees with reference mark (4).

Gage reading will indicate amount of

reshimming (as necessary).

NOTE

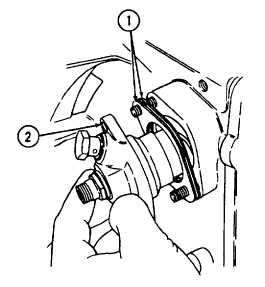

The end of delivery is delayed or advanced by adding or removing shims (1) to injection pump

(2). The general rule for shimming is as follows: More shims = end of delivery later (lower

number of degrees) Less shims = end of delivery earlier (higher number of degrees)

6

Remove fuel shutoff clamp 668 383 00 from fuel hose.

7

After correction of shimming, repeat steps 1 and 2 for checking purposes.

4-32

|