|

| |

TM 5-4320-306-24

4-13.

REPLACE/REPAIR CRANKCASE ASSEMBLY (Continued)

d

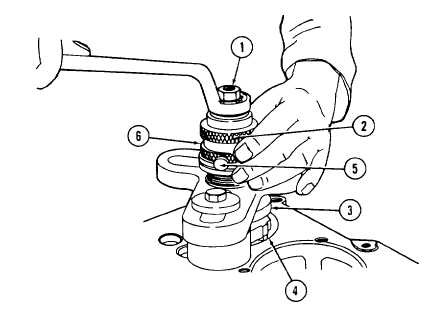

Turn spindle (1) and knurled nut (2) clockwise (viewing unit from top) until seat cutter and holder (3) just

contact cylinder seat (4) Lock knurled nut in place with setscrew (5).

CAUTION

Do not turn spindle counterclockwise. This will damage the cylinder seat and may damage the

crankcase bore. Turn only in clockwise direction as shown.

5

Turn spindle (1) clockwise to smooth, flatten, and reface cylinder seat (4) as necessary. Do not remove more

material than absolutely necessary.

6

After refacing cylinder seat (4), loosen setscrew (5), and turn knurled nut (2) counterclockwise to back seat cutter

and holder (3) away from cylinder seat (4). Withdraw seat cutter holder with positioning screw and remove

refacing tool (6).

7

If other cylinder seat also needs to be refaced, smoothed, and or flattened, repeat above process starting with

step 4.

NOTE

If cylinder seats are refaced, check piston top clearance when cylinder and cylinder head are

installed. If too much of the cylinder seat has not been removed, the difference in height can be

corrected with additional shims when the cylinder is installed. Follow procedure in paragraph 4-9.

4-115

|