|

| |

TM 5-4320-306-24

4-12.

REPLACE/REPAIR CRANKSHAFT ASSEMBLY (Cont inued)

2

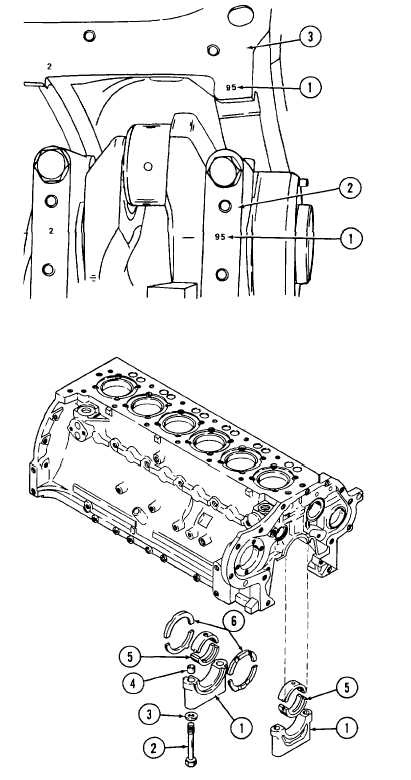

Check the matchmark (1) on each

bearing cap (2) and match it with the

corresponding matchmark (1) on the

crankcase

(3).

The

matchmarks

indicate direction of installation as

well as location. The number and

direction of the matchmark on each

bearing cap shall be the same as the

matchmark

at

each

crankcase

position.

3

In each bearing cap (1), install bolts

(2), washers (3) and dowel bushings

(4).

4

Coat

main

bearings

(5)

with

lubricating oil.

5

Coat stop rings (6) with grease and

position on bearing caps so that

each stop ring lines up with groove

on stop ring face of bearing cap. Be

sure to install the two stop rings on

the bearing caps from which they

were removed.

6

Starting with the center locating

bearing and working toward the front

and rear bearings, install correctly

matched main bearings (5), bearing

caps (1), and stop rings (6) in the

corresponding bearing brackets of

the crankcase.

7

Make sure main bearing half (5) with

oil

groove

is

installed

in

the

crankcase, and that each bearing

cap (1) is properly alined by dowel

bushings (4).

8

Tighten bolts (2) alternately and

evenly to 22.13 ft-lb (30 N.m) torque

with socket wrench. Using torque

gage No. 101910, tighten bolts an

additional 60 degrees. Following the

same pattern, tighten bolts again an

additional 45 degrees.

4-101

|