|

| |

TM 5-4320-306-24

4-12.

REPLACE/REPAIR CRANKSHAFT ASSEMBLY (Continued)

cloth evenly around circumference of crankpin or journal until surface is polished smooth. If wet crocus cloth is

not effective, use emery cloth, 120 grit for removing imperfections and 240 grit for finishing. Polish smooth with

wet crocus cloth. Use of a piece of rawhide or other suitable rope wrapped around the emery cloth or crocus

cloth and drawn back and forth will minimize the possibility of an out-of-round condition developing (keep the

strands of rawhide apart to avoid bind). If rawhide or rope is not used, the crankshaft should be rotated at

intervals If the above procedure is not effective or imperfections are too great, the crankshaft must be replaced.

3

All crankpin and journal fillets must have a 0.1693 to 0.1772 inch (4.30 to 4 50 mm) radius between crank cheek

and crankpin or journal and must not have any sharp grind marks. Fillet must blend smoothly into crankpin or

journal and crank cheek, and must be free of scratches. Check radius with a fillet gage and polish smooth any

slight imperfections with crocus cloth wet with diesel fuel oil. If radius is too far outside specified limits, the

crankshaft must be replaced.

4

Stone edges of all oil holes in crankpin and journal surfaces with surfacing stone to provide a smooth radius.

WARNING

Death or serious injury could occur if diesel fuel oil is not handled carefully. Use in a well-

ventilated area away from open flame, arcing equipment, ignition sources, heaters, or excessive

heat. Always store fuel in proper, marked containers. DO NOT SMOKE.

5

Polish ground surfaces to an 8 to 12 RMS finish with crocus cloth wet with diesel fuel oil.

6

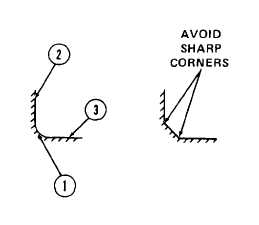

Inspect crankshaft thrust surfaces If slightly worn or grooved, smooth out and polish surfaces with wet crocus

cloth Make sure to leave a 0.1693 to 0.1772 inch (4 30 to 4.50 mm) radius (1) on crankshaft between each thrust

surface (2) and bearing journal (3) or crankpin.

7

Clean up minor burrs and gouges of the shaft seal and preformed packing seats with emery cloth. Repair any

minor damage, nicks, burrs, rust, or corrosion. If defects cannot be removed, replace the rear-end cover.

4-99

|