|

| |

TM 5-4320-306-24

4-11. REPLACE/REPAIR CONNECTING ROD ASSEMBLY (Continued)

5

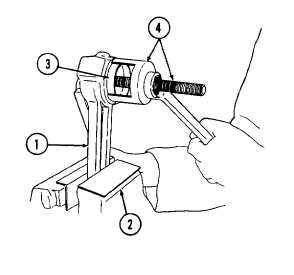

Clamp connecting rod (1) in a padded vise (2) and remove small-end bushing (3) with piston pin bush inserter

No. 131310 (4).

CLEANING/INSPECTION :

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard's Solvent) is potentially dangerous. Avoid repeated and

prolonged breathing of vapors and skin contact with the liquid. Do not use near open flame, arcing

equipment, or other ignition sources. Always wear eye protection and protective clothing. The flash point

of P-D-680 is 100° to 138°F (38° to 59°C).

Death or serious injury could occur if compressed air is directed against the skin. Do not use compressed

air for cleaning or drying unless the pressure is/has been reduced to 30 psi (2.11 kgcm2) or less. When

working with compressed air always use chip guards, eye protection, and other personal protective

equipment.

1

Clean connecting rod components (1 through 7) with dry cleaning solvent and dry with compressed air. Remove

any carbon deposits with a wire brush.

2

Clean inside surface of small-end bushing, connecting rod, and bearing shells.

3

Blow compressed air through the drilled oil passage in connecting rod, so that air flows freely through oil holes in

connecting rod and bushing to clean them out.

4-83

|