|

| |

TM 5-4320-306-24

4-9. REPLACE/REPAIR CYLINDER ASSEMBLY (Continued)

5

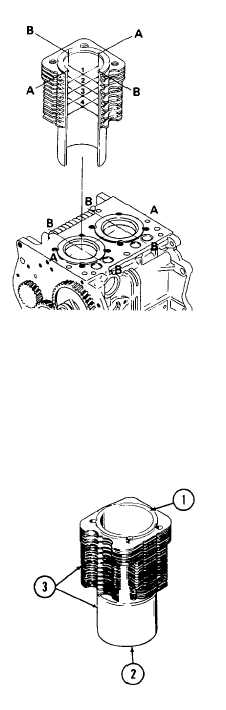

Measure cylinder bore at levels 1 to 4 of engine

centerline axis A and crossline axis B. Cylinder

bore should be 3.9370 to 3.9457 inches (100.0 to

100.22 mm). If 3.9488 to 3.9575 inches (100.3 to

100.52 mm) wear limits have been reached or

exceeded, replace cylinder and/or piston.

6

If measurements on axis A and axis B are

different, cylinder is out-of-round or has high

spots. Replace cylinder and/or piston as

necessary.

7

Check that top joint face (1) and bottom joint face

(2) are smooth and flat If severely damaged,

replace cylinder (3) and/or piston. If joint faces

have only minor nicks or burrs or minor high

spots, repair.

8

Replace a cylinder and/or piston if:

a.

It is cracked, severely scored, or has a high

ridge at the top of its inner surface as

described in step 3.

b.

Out-of-round exceeds the limits described

in step 4.

c.

Cylinder bore exceeds the limits described

in step 4.

4-67

|