|

| |

TM 5-4320-306-24

4-8. REPLACE/REPAIR CAMSHAFT (Continued)

17

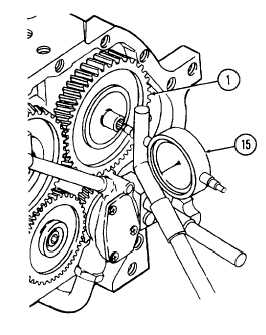

Install camshaft (1) and measure axial clearance using dial gage (15) mounted on crankshaft with a magnetic

adapter. Clearance should be 0.0098 to 0.0236 inch (0.250 to 0.600 mm). If clearance is not within specified

limits, recheck bushing. Make sure bushing bore is within specified limits and bushing is seated properly in

crankcase. Replace in accordance with paragraph 4-13 if necessary.

18

Recheck bearing journal on camshaft for wear. Replace if worn close to camshaft gear. Recheck washer and

camshaft gear for wear. Recheck axial clearance to see that it is within specified limits.

REPAIR:

WARNING

Death or serious injury could occur if diesel fuel oil is not handled carefully. Use in a well-ventilated area

away from open flame, arcing equipment, ignition sources, heaters, or excessive heat. Always store fuel

in proper, marked containers. DO NOT SMOKE.

Death or serious injury could occur if compressed air is directed against the skin. Do not use compressed

air for cleaning or drying unless the pressure is/has been reduced to 30 psi (2.11 kgcm2) or less. When

working with compressed air always use chip guards, eye protection, and other personal protective

equipment.

1

If contact surfaces are severely scratched, worn, or scored, replace camshaft (1). Repair minor nicks, burrs, or

wear with surfacing stone. Clean with diesel fuel oil and dry with compressed air.

2

Use crocus cloth to repair minor nicks, burrs, or wear on camshaft gear (4). Clean with diesel fuel oil and dry

with compressed air. Replace camshaft (1) if there is severe cracking or damage to gear (2).

3

Replace bushing (9) in accordance with paragraph 4-13 if bore is outside specified limits. Do not repair bushing.

4

Replace bearing journal (6) if diameter is outside specified limits. Do not repair bearing journal.

4-62

|