|

| |

TM 5-4320-306-24

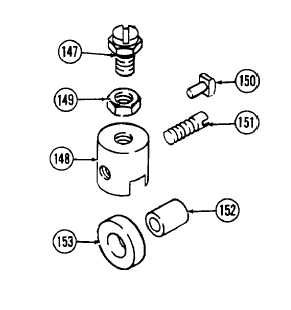

4-4. REPAIR INJECTION PUMP (Continued)

a.

Measure and record height of screw (147) above

tappet (148).

b.

Loosen nut (149), and remove screw (147) and nut

Remove guide pin (150).

c.

Press stud (151) from bushing (152) and tappet (148).

Remove bushing from roller (153)

d.

Inspect screw (147) for thread damage and for worn or

crushed end. Replace if damaged.

e.

Inspect tappet (148) for pressure marks or scoring.

Remove light marks and scoring using crocus cloth.

f.

Inspect stud (151) for grooving Replace if grooved or

bent.

g.

Inspect nut (149), guide pin (150), bushing (152), and

roller (153) for heavy wear. Replace damaged parts

h.

Press bushing (152) into roller (153), and position roller in tappet (148).

i.

Press stud (151) through tappet (148) and into bushing (152) Install guide pin (150), nut (149), and screw (147).

Turn screw to height above tappet body as recorded in step a above.

j.

Install guide pin (150), nut (149), and screw (147). Turn screw to height above tappet body as recorded in step a

above.

k.

Tighten nut (149) to secure screw (147).

3

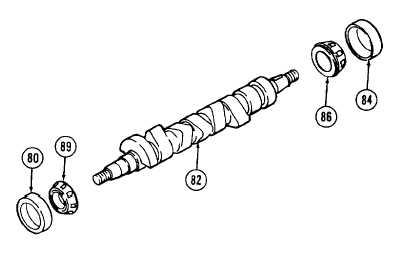

Inspect camshaft (82) for cracks or

distortion. Inspect threads for damage

Inspect cam lobes for chipping, scoring,

grooving, or cracks. If damaged, replace

camshaft.

4

Inspect bearing cups (80 and 84) and bearing

cones (86 and 89) for flat areas, pitting,

cracks, or chipping. Inspect bearing cones

for cracked races Replace mating bearing

cups and bearing cones as a pair if either is

damaged

4-16

|