|

| |

TM 5-4320-306-24

3-15. TEST/REPLACE FUEL INJECTORS (Continued)

WARNING

Death or serious injury could occur if diesel fuel oil is not handled carefully Use in a well-

ventilated area away from open flame, arcing equipment, ignition sources, heaters, or excessive

heat. Always store fuel in proper, marked containers. DO NOT SMOKE.

2

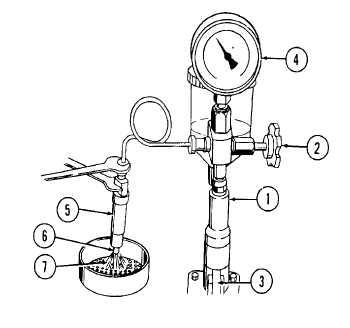

Connect Bosch pump outfit No 003-3345. (1)

3

Fill Bosch pump fuel container 3/4 full with diesel

fuel oil. Do not overfill.

4

Make sure pressure valve (2) is turned all the way

clockwise and closed. Pump up air pressure in unit

by pumping the pump hand lever (3) up and down

several times.

5

Slowly turn pressure valve (2) counterclockwise.

As the valve starts to open, read fuel injection

pressure on gage (4). Continue to open valve to

increase fuel injection pressure to injector (5) until

fuel sprays out of nozzle (6). Read and record

injection pressure. Injection pressure should be

2611 to 2727 psi (18000 to 18 800 kPa) for a new

injector, or 2538 to 2654 psi (17 500 to 18 300 kPa)

for an injector in operation and being tested.

Injection pressure may be adjusted if it does not fall

within the limits above. Refer injector to general

support for adjustment or repair, and replace

injector.

6

Check fuel spray (7) pattern from injector nozzle (6). Fuel should spray out in several evenly spaced jets of

equal thickness and with no mist surrounding the jets. If spray pattern does not conform to above, refer injector

(3) to general support maintenance for repair, and replace injector. If injector nozzle drips fuel at approximately

2100 to 2360 psi (14 500 to 16 300 kPa) before it has reached recommended injection pressure, refer injector to

general support maintenance for repair, and replace injector. If nozzle drips fuel after injection pressure test,

refer injector to general support for repair, and replace injector.

3-69

|