|

| |

TM 5-4320-306-24

3-11. REPLACE/REPAIR OIL PUMP ASSEMBLY (Continued)

3

Inspect suction pipe (5) and hydraulic pipe (14) for holes, clogs, or crimps that would restrict oil flow

or cause leaks at connections. Replace damaged or bent pipes or pipes that cannot be cleaned.

4

Inspect suction pipe (5) with screen for clogs or holes in screen. Clean screen by soaking in solvent and

brushing lightly with scrub brush If the screen is torn or cannot be cleaned, replace suction pipe.

5

Inspect cap screw/nut (4) for stripped or worn threads. Replace if stripped or worn.

6

Inspect journal (18) bearing surface for wear or pitting. If the surface is damaged or pitted, the journal

must be repaired or replaced.

7

Inspect bushing (19) and the bushing contacting hole of the journal for wear, chips, or signs of shearing.

Replace damaged components.

8

Inspect idler gear (16) teeth for worn, chipped, or pitted teeth or contact surfaces. If gear is damaged or

pitted, it must be repaired or replaced.

9

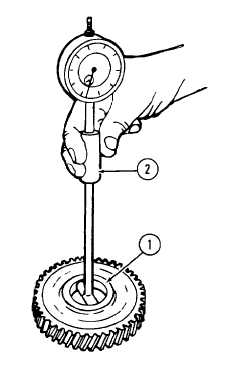

Measure the bushing bore (1) of the idler gear with a dial

indicator (2). The vertical clearance must not exceed

1.576 inches (40.030 mm). If clearance exceeds this

limit, replace the bushing.

REPAIR:

1

Do not attempt repairs on interior of oil pump. Replace oil pump.

2

Remove any rust or corrosion from oil pump outer gear.

3

Repair only minor nicks or burrs on outer gear with crocus cloth. If gear is severely damaged, replace oil pump.

4

Replace any stripped or damaged hardware.

3-54

|