|

| |

TM 5-4320-305-24

4-12. REPLACE/REPAIR CRANKSHAFT ASSEMBLY (Continued)

4

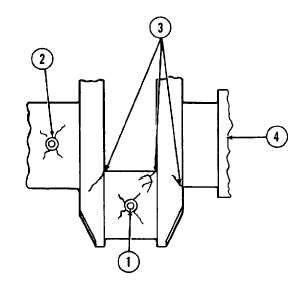

Visually inspect crankshaft journals and crankpins for

overheating, cracking, excessive wear, or other

damage. Visually inspect for cracks which start at a

crankpin or journal oil hole (1 or 2) and follow the

journal or crankpin surface at an angle of 45 degrees

to the axis. Inspect for cracks in critical fillet areas

(3). Replace crankshaft (4) if cracks are visible.

Inspect for minute cracks using MIL-I6868 Magnetic

Particle Inspection. Replace crankshaft if any cracks

are found or if it has been overheated.

5

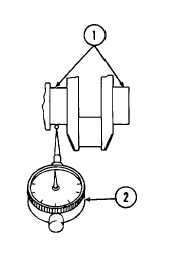

Check alinement at adjacent center and main bearing journals (1)

with a dial indicator (2). Maximum allowable runout is 0.002 inch

(0.0508 mm). Replace crankshaft, if necessary.

6

Inspect crankpins.

a.

Measure diameter of each crankpin (1) at points 1 and 2 and along axes A and B with micrometer.

Measure width of crankpin at point 3. Measure radius of fillets (2) between crankpin and crank

cheek (3).

b.

Diameter should be 2.5185 to 2.5193 inches (63.971 to 63.99 mm). If any measurement is outside

the specified limits, crankshaft must be replaced.

4-96

|